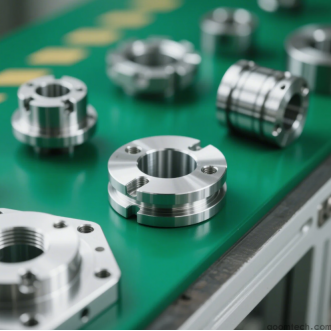

CNC партидна обработка на алуминиеви части

Като водещ CNC machining service provider, AOOM Technologies specializes in high-volume aluminum component manufacturing with precision and efficiency. This article will explore the critical aspects of CNC batch machining for aluminum parts, addressing the key concerns of procurement managers and engineers.

Разбиране на CNC партидна обработка за алуминий

Партидната обработка се отнася до производството на идентични алуминиеви компоненти в предварително определени количества, използвайки CNC технология. В AOOM използваме усъвършенствани 3/4/5 -осови CNC машини, способни да обработват алуминиеви сплави от 100 до 700 серии, осигурявайки измерителна точност в рамките на ±.01mm.

Ключови стъпки на процеса

1. Material Preparation: Selection of appropriate aluminum grade based on mechanical requirements

2. Fixture Design: Custom workholding solutions for batch consistency

3. Toolpath Optimization: CAM programming for maximum material removal rates

4. Quality Control: In-process inspection with CMM and surface roughness testers

Предимства на нашата услуга за обработка на партиди

• Cost-effective production for quantities from 50-10,000+ units

• 15-30% faster cycle times through optimized tooling strategies

• Dedicated production cells for aluminum-specific machining

• ISO 9001-certified quality management system

Индустриални приложения

Нашите възможности за партидна обработка служат:

- Aerospace: Structural components and housings

- Automotive: Engine parts and transmission elements

- Electronics: Heat sinks and enclosures

- Medical: Instrumentation components

С над 12 години опит в алуминиевата обработка, AOOM Technologies доставя надеждни CNC batch machining solutions that balance precision, speed, and cost-efficiency. Contact our engineering team today to discuss your specific project requirements.

CNC части обработка производител

CNC части обработка производител

Какви продукти могат CNC машина

Какви продукти могат CNC машина

CNC Берилиев меден обработващ процес

CNC Берилиев меден обработващ процес

Доставчик на CNC хардуерна обработка

Доставчик на CNC хардуерна обработка