Каква точност може да постигне CNC 3-осна обработка?

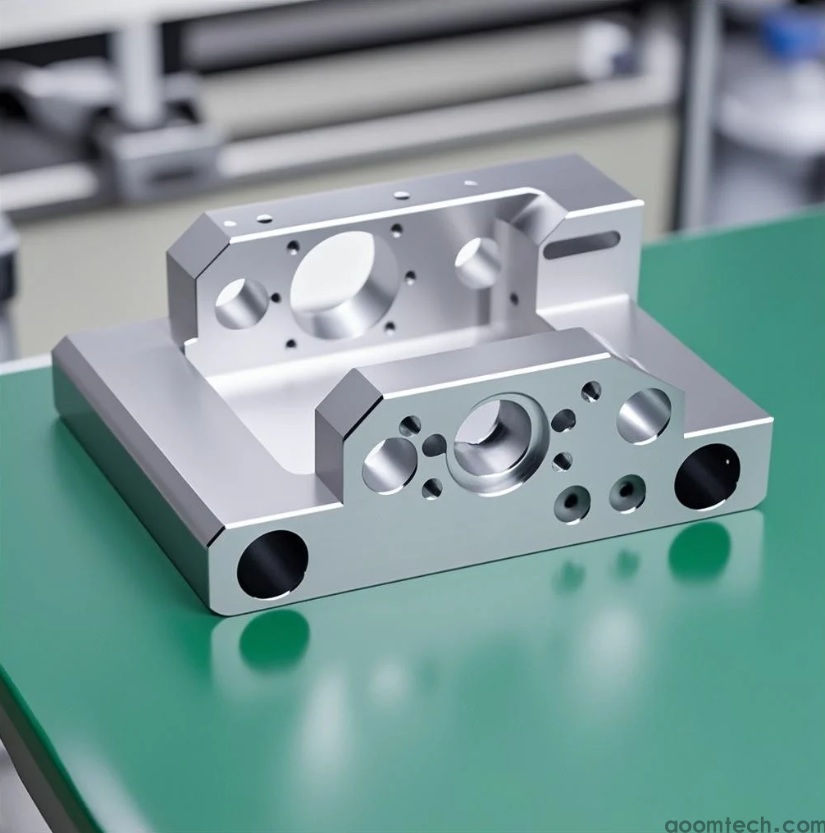

Като професионалист CNC machining service provider, AOOM Technology understands that precision is the cornerstone of manufacturing excellence. When clients inquire about CNC 3-axis machining capabilities, they are typically seeking clarity on achievable tolerances and surface finishes for their projects.

Разбиране на CNC 3-осна обработка прецизност

Стандарт 3-axis CNC machines can typically maintain tolerances of ±.005" (±.127mm) for most materials, with some high-performance machines achieving ±.001" (±.025mm) under optimal conditions. The actual precision depends on multiple factors including machine calibration, tooling quality, material characteristics, and operator expertise.

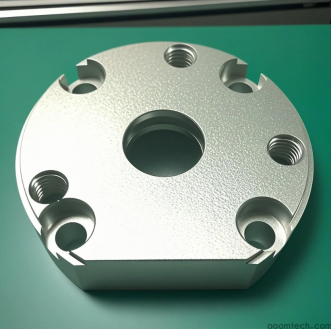

Ключови фактори, засягащи точността на обработката

1. Machine Rigidity : Our German and Japanese CNC equipment maintains exceptional stability

2. Tooling Selection : We use premium carbide end mills from leading brands

3. Temperature Control : Climate-controlled workshop prevents thermal expansion

4. Measurement Systems : Mitutoyo CMM machines verify part dimensions

Прецизните възможности на AOOM

Чрез нашите процеси, сертифицирани по ISO 9001, ние последователно предоставяме:

- Standard tolerance: ±.005" (±.127mm)

- High-precision tolerance: ±.001" (±.025mm)

- Surface finishes down to Ra .8μm (32μin)

Our engineering team can recommend optimal machining strategies to balance precision requirements with cost efficiency.

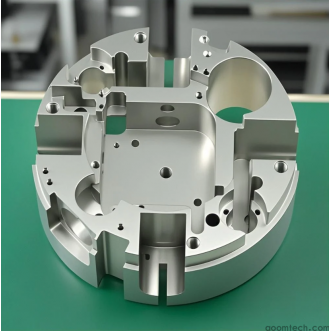

Приложения на прецизна 3-осна обработка

Тази технология обслужва индустрии, изискващи строги толерантности:

• Aerospace components

• Medical device prototypes

• Automotive parts

• Industrial automation systems

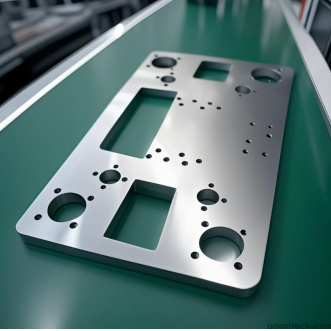

В AOOM Technology комбинираме съвременно оборудване с десетилетия опит в обработката, за да доставим прецизни компоненти, които отговарят на вашите точни спецификации. Свържете се с нашия инженерен екип, за да обсъдите специфичните изисквания на вашия проект.

CNC прецизна обработка на части: Кой производител предлага н

CNC прецизна обработка на части: Кой производител предлага н

Коя е най-добрата фабрика за прецизна хардуерна обработка на

Коя е най-добрата фабрика за прецизна хардуерна обработка на

CNC алуминиеви части масово производство Производител

CNC алуминиеви части масово производство Производител

CNC партидна обработка на алуминиеви части: ключови съображе

CNC партидна обработка на алуминиеви части: ключови съображе