Hvilke materialer kan CNC maskine?

Som professionel CNC machining service provider, AOOM Technology frequently encounters this fundamental question from engineers, procurement managers, and business owners. Understanding material compatibility is crucial for achieving optimal machining results and cost efficiency.

Metaller: De mest almindelige CNC bearbejdningsmaterialer

CNC-maskiner udmærker sig ved behandling af forskellige metaller, herunder aluminium (6061, 7075), rustfrit stål (303, 304, 316), messing, kobber og titanium. Aluminium er især populært på grund af sin fremragende bearbejdningsevne og styrke-til-vægt-forhold, hvilket gør det ideelt til luftfarts- og bilindustrien.

Ingeniørplast til specialiserede applikationer

Ud over metaller, CNC machining handles numerous engineering plastics like ABS, PEEK, Delrin, and Nylon. These materials are chosen for their electrical insulation properties, chemical resistance, or low friction coefficients in medical devices and electronic components.

Avancerede materialer og kompositter

Moderne CNC-teknologi kan behandle avancerede materialer, herunder kulfiberkompositter, Inconel og wolfram. Disse kræver specialiserede værktøj og parametre, som AOOM Technologys erfarne teknikere mestrer gennem vores ISO 9001-certificerede processer.

Overvejelser om materialevalg

Når man vælger materialer til CNC machining, consider mechanical requirements, environmental factors, and post-processing needs. Our engineering team at AOOM provides comprehensive material consultation to ensure your project's success from prototype to mass production.

Besøg aoomtech.com to explore our material capabilities and request a free project evaluation with our technical experts.

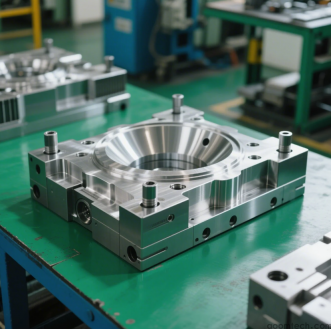

CNC Precision Produktbearbejdningsproces

CNC Precision Produktbearbejdningsproces

CNC Aluminium Parts Producent: Hvordan man vælger det bedste

CNC Aluminium Parts Producent: Hvordan man vælger det bedste

Hvilke materialer kan CNC maskine?

Hvilke materialer kan CNC maskine?

CNC ikke-standard præcision bearbejdning tilpasning

CNC ikke-standard præcision bearbejdning tilpasning