CNC Bolt bearbejdningsproces

I præcision fremstilling, CNC bolt machining process stands as a critical operation for industries requiring high-tolerance fasteners. As a leading CNC machining service provider, AOOM Technology delivers exceptional bolt manufacturing solutions tailored to aerospace, automotive, and industrial applications.

Forståelse af CNC Bolt bearbejdning

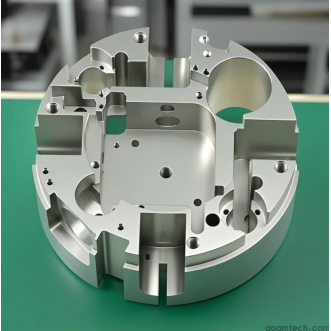

Den CNC bolt machining process involves computer-controlled lathes or milling machines transforming raw metal bars into precision bolts through sequential operations including turning, threading, head forming, and surface finishing. Our 5-axis CNC machines achieve ±.005mm tolerances, ensuring perfect thread engagement and load distribution.

Nøglefordele ved vores CNC boltproduktion

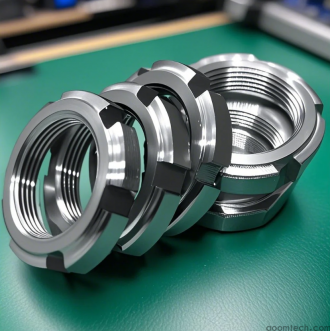

1. Material Versatility: We machine bolts from stainless steel, titanium, aluminum, and exotic alloys

2. Thread Precision: ACME, UN, metric, and custom thread profiles with certified accuracy

3. Surface Treatments: Optional plating, anodizing, or passivation for corrosion resistance

4. Batch Flexibility: From prototype quantities to 100,000+ production runs

Tekniske specifikationer

Vores CNC bolt machining process accommodates:

• Diameter range: M1.6 to M64

• Length-to-diameter ratios up to 12:1

• Head types: Hex, socket, flange, and custom designs

• Compliance with ISO 898, ASME B18.2, and DIN standards

Hvorfor vælge AOOM teknologi?

Med 15+ års CNC-bearbejdningsekspertise kombinerer vi avancerede schweiziske drejebænke med streng kvalitetskontrol (herunder 100% trådmåling) for at levere bolte med perfekte mekaniske egenskaber. Vores ingeniører optimerer hver bearbejdningsparameter - fra skærehastigheder til værktøjsstier - hvilket sikrer maksimal trækstyrke og træthedsbestandighed.

Anmode om en gratis gennemgang af projektet på www.aoomtech.com to experience precision bolt manufacturing that eliminates assembly issues and reduces total fastener costs.

CNC-aluminiumsproduktbehandlingstilbud

CNC-aluminiumsproduktbehandlingstilbud

CNC Titanium Alloy bearbejdningsproces Flow

CNC Titanium Alloy bearbejdningsproces Flow

Hvordan CNC bearbejdning processer store forme

Hvordan CNC bearbejdning processer store forme

CNC ikke-standard brugerdefineret bearbejdningsfabrikant

CNC ikke-standard brugerdefineret bearbejdningsfabrikant