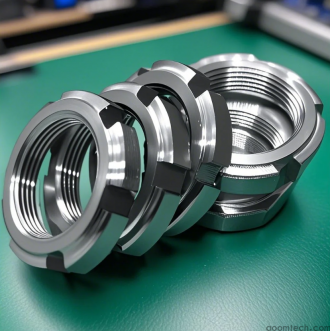

CNC batch bearbejdningsproces til aluminiumsdele

Som førende CNC machining service provider, AOOM Technologies specializes in high-volume aluminum component manufacturing with precision and efficiency. This article will explore the critical aspects of CNC batch machining for aluminum parts, addressing the key concerns of procurement managers and engineers.

Forståelse af CNC-battbearbejdning til aluminium

Batchbearbejdning refererer til produktion af identiske aluminiumskomponenter i forudbestemte mængder ved hjælp af CNC-teknologi. Hos AOOM anvender vi avanceret 3/4/5 -akse CNC-maskiner, der er i stand til at håndtere aluminiumslegeringer fra 100 til 700 serier, hvilket sikrer dimensionel nøjagtighed inden for ± 0,01 mm.

Nøgleprocestrin

1. Material Preparation: Selection of appropriate aluminum grade based on mechanical requirements

2. Fixture Design: Custom workholding solutions for batch consistency

3. Toolpath Optimization: CAM programming for maximum material removal rates

4. Quality Control: In-process inspection with CMM and surface roughness testers

Fordele ved vores Batch Machining Service

• Cost-effective production for quantities from 50-10,000+ units

• 15-30% faster cycle times through optimized tooling strategies

• Dedicated production cells for aluminum-specific machining

• ISO 9001-certified quality management system

Brancheapplikationer

Vores batchbearbejdningsfunktioner tjener:

- Aerospace: Structural components and housings

- Automotive: Engine parts and transmission elements

- Electronics: Heat sinks and enclosures

- Medical: Instrumentation components

Med over 12 års erfaring med bearbejdning af aluminium leverer AOOM Technologies pålidelig CNC batch machining solutions that balance precision, speed, and cost-efficiency. Contact our engineering team today to discuss your specific project requirements.

CNC højpræcisionsdelebehandling

CNC højpræcisionsdelebehandling

Metode til beregning af CNC-bearbejdningsomkostninger

Metode til beregning af CNC-bearbejdningsomkostninger

CNC bearbejdning Brugerdefineret mekaniske dele producent

CNC bearbejdning Brugerdefineret mekaniske dele producent

CNC produkt tilpasset bearbejdning: præcisionsløsninger til

CNC produkt tilpasset bearbejdning: præcisionsløsninger til