CNC Turning Tilpasningstjenester til præcisionsfremstilling

i moderne produktion, CNC turning customization has become a cornerstone for industries requiring high-precision components. As a trusted provider at AOOM Technologies, we specialize in delivering tailored solutions that meet stringent quality standards while optimizing production efficiency.

Hvad er CNC Turning Customization?

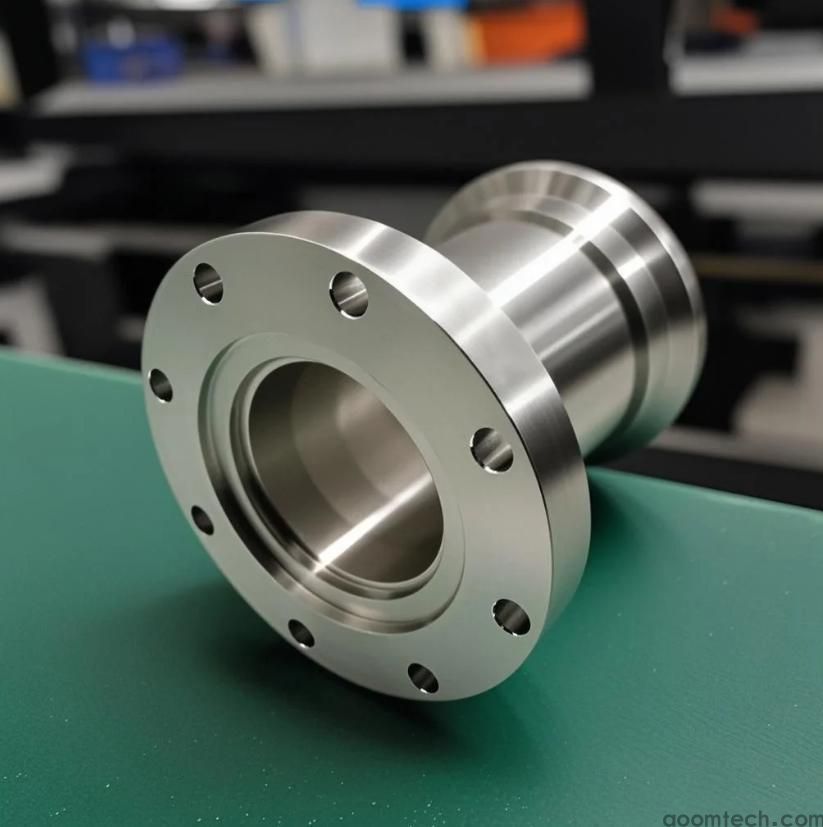

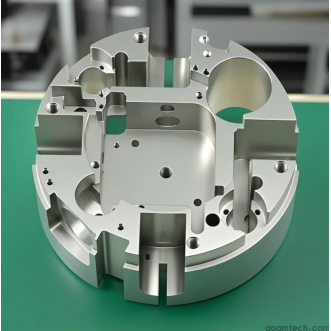

CNC drejning tilpasning henviser til processen med at skabe præcisionsdele ved at dreje et emne, mens et skæreværktøj fjerner materiale. Denne metode er ideel til at producere cylindriske eller koniske former med stramme tolerancer (så lave som ± 0,005 mm). Vores avancerede CNC-drejebænk på AOOM understøtter multiakseoperationer, der muliggør komplekse geometrier som tråde, riller og koniske funktioner i materialer, der spænder fra aluminiumslegeringer til titanium.

Nøglefordele ved at vælge AOOM til brugerdefineret CNC-drejning

1. Material Expertise: We machine over 50+ metals/plastics, including challenging materials like Inconel and PEEK.

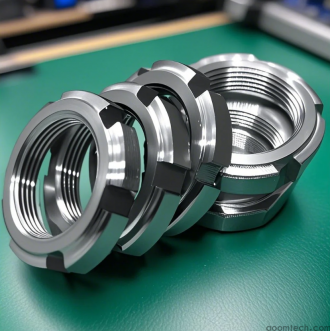

2. Precision Guarantee: ISO 9001-certified processes ensure dimensional accuracy up to IT6 grade.

3. Rapid Prototyping: 3-5 day lead times for prototype batches through our dedicated quick-turn service.

4. Surface Finish Options: From Ra .8μm mirror finishes to powder coating/anodizing.

Industrier, vi betjener med brugerdefinerede drejeløsninger

• Aerospace: Flight-critical components like hydraulic fittings

• Medical: FDA-compliant surgical instrument parts

• Automotive: High-volume fuel injection components

• Energy: Corrosion-resistant valve bodies for offshore applications

Vores End-to-End Tilpasning Workflow

1. Design Consultation: DFM analysis using SolidWorks/Creo software

2. Material Selection: Technical guidance on optimal grade selection

3. Process Planning: Toolpath optimization for minimal material waste

4. Quality Validation: CMM inspection with comprehensive reports

Hos AOOM Technologies kombinerer vi tyskfremstillede DMG MORI-maskiner med 15+ års bearbejdningsekspertise for at levere CNC turning customization that exceeds expectations. Request your free project evaluation today to experience precision manufacturing redefined.

CNC-aluminiumsproduktbehandlingstilbud

CNC-aluminiumsproduktbehandlingstilbud

CNC Titanium Alloy bearbejdningsproces Flow

CNC Titanium Alloy bearbejdningsproces Flow

Hvordan CNC bearbejdning processer store forme

Hvordan CNC bearbejdning processer store forme

CNC ikke-standard brugerdefineret bearbejdningsfabrikant

CNC ikke-standard brugerdefineret bearbejdningsfabrikant