CNC ikke-standard brugerdefineret bearbejdningsfabrikant

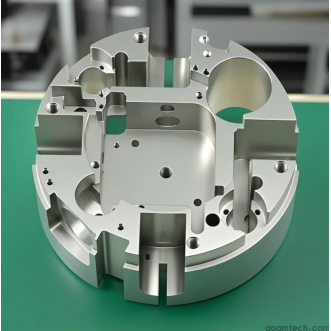

Inden for præcisionsfremstilling finder man en pålidelig CNC non-standard custom machining manufacturer is critical for industries requiring bespoke components. AOOM Technology specializes in delivering high-precision, tailor-made CNC machining solutions to meet diverse industrial demands. This article explores the capabilities, processes, and advantages of partnering with a professional manufacturer like AOOM.

Hvad er CNC ikke-standard brugerdefineret bearbejdning?

Ikke-standard tilpasset bearbejdning refererer til produktion af komponenter, der afviger fra standardstørrelser, former eller materialer. I modsætning til masseproducerede dele kræver disse specialiserede CNC machining techniques to achieve unique geometries, tight tolerances, or complex features. Applications span aerospace, automotive, medical devices, and robotics, where off-the-shelf solutions fall short.

De vigtigste fordele ved at vælge AOOM-teknologi

1. Precision Engineering: Our advanced CNC machines (3/4/5-axis) ensure micron-level accuracy for intricate designs.

2. Material Versatility: We work with metals (aluminum, titanium, stainless steel), plastics, and exotic alloys.

3. End-to-End Service: From CAD/CAM design support to post-processing (anodizing, polishing), we streamline production.

4. Scalability: Prototyping to bulk orders, all under strict ISO 9001-certified quality control.

Industrier vi tjener

AOOM'er non-standard CNC machining caters to:

Aerospace: Lightweight yet durable components for flight-critical systems.

Medical: Biocompatible implants and surgical instruments with sterile finishes.

Automotive: High-performance parts for electric vehicles and custom modifications.

Hvorfor samarbejde med AOOM?

Med et årti med ekspertise kombinerer AOOM Technology banebrydende maskiner med erfarne ingeniører for at løse komplekse produktionsudfordringer. Vores klientcentrerede tilgang sikrer levering til tiden, konkurrencedygtige priser og urokkelig kvalitet - hvilket gør os til en pålidelig global leverandør. Besøg aoomtech.com to discuss your project requirements today.

CNC rustfrit stål bearbejdning Citat: Faktorer, der påvirker

CNC rustfrit stål bearbejdning Citat: Faktorer, der påvirker

CNC produktfremstilling og forarbejdning producent

CNC produktfremstilling og forarbejdning producent

CNC bearbejdning rustfrit stål medicinske dele

CNC bearbejdning rustfrit stål medicinske dele

CNC-aluminiumsproduktbehandlingstilbud

CNC-aluminiumsproduktbehandlingstilbud