CNC rustfrit stål bearbejdning Citat: Faktorer, der påvirker prisfastsættelsen

Når sourcing CNC stainless steel machining services, obtaining an accurate quote is critical for budget planning. This guide breaks down key pricing factors and explains how AOOM combines competitive pricing with precision engineering to meet industrial demands.

Hvad bestemmer CNC rustfrit stål bearbejdningsomkostninger?

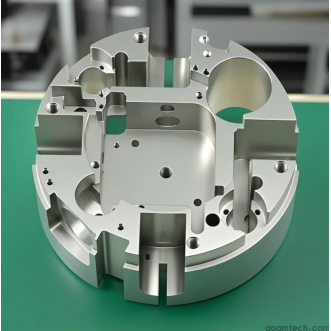

Materialekvalitet (304/316 vs. speciallegeringer), delkompleksitet (stramme tolerancer under ± 0,01 mm), batchstørrelse (prototype vs. masseproduktion) og sekundære processer (afbrydning, polering) påvirker væsentligt CNC machining quotes. Our ISO 9001-certified facility uses AI-powered cost estimation tools to provide transparent pricing within 24 hours.

AOOMs konkurrencemæssige fordele i rustfrit stål CNC

Med 12 schweiziske CNC-drejebænke og 5-aksede fræsecentre opnår vi 99,8% levering til tiden for rustfri komponenter. Proprietary toolpath optimering reducerer bearbejdningstiden med 15-30%, hvilket giver besparelser til kunderne. Casestudie: En producent af medicinsk udstyr sparede 22% på 316L kirurgiske instrumentdele gennem vores DFM (Design for Manufacturing) analyse.

Sådan får du dit tilpassede tilbud

Upload tegninger/STEP filer via AOOM's online quoting system or email sales@aoomtech.com. For complex projects, request a free engineering review. We serve aerospace, automotive, and semiconductor industries with ITAR-compliant options.

CNC rustfrit stål bearbejdning Citat: Faktorer, der påvirker

CNC rustfrit stål bearbejdning Citat: Faktorer, der påvirker

CNC produktfremstilling og forarbejdning producent

CNC produktfremstilling og forarbejdning producent

CNC bearbejdning rustfrit stål medicinske dele

CNC bearbejdning rustfrit stål medicinske dele

CNC-aluminiumsproduktbehandlingstilbud

CNC-aluminiumsproduktbehandlingstilbud