Precision Iron CNC bearbejdningstjenester: En omfattende guide til købere

Hej der, indkøbsledere og ingeniører! 👋 Er du træt af sourcing precision iron parts that end up with inconsistent quality or delayed deliveries? You're not alone. Finding a reliable partner for your CNC machining needs can feel like a huge challenge. This guide dives deep into everything you need to know about precision iron CNC machining services, answering your core question: What should I really look for? Let's get started.

Hvad Er Precision Iron CNC Machining Services?

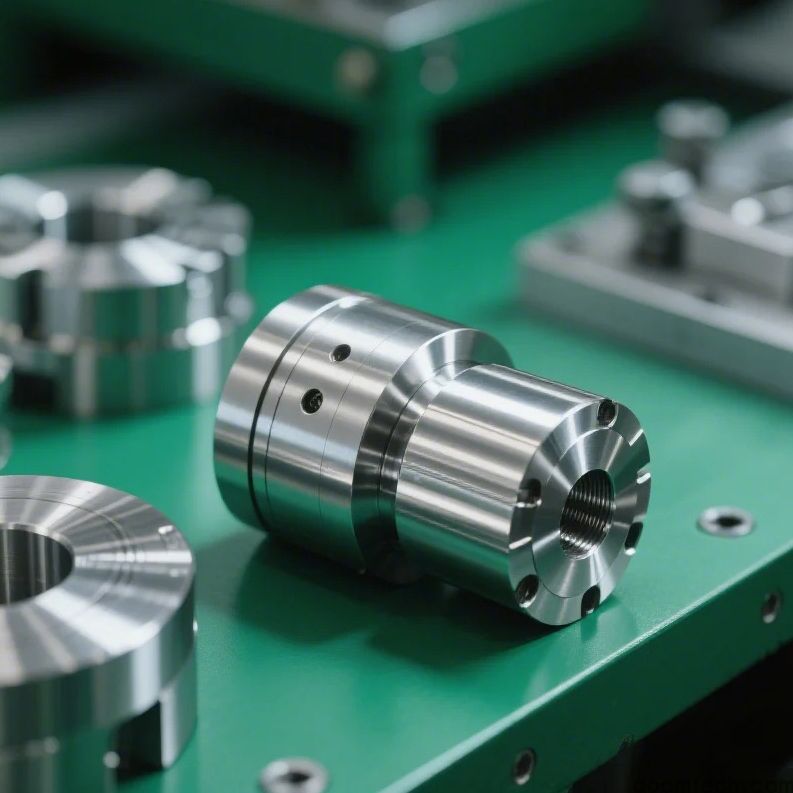

Kort sagt, det er en superkontrolleret måde at forme jern i præcis de dele, du har brug for. Forestil dig en computerstyret maskine udskæring, boring og skære rå jernblokke med utrolig nøjagtighed. Det er hjertet af det. Men det handler ikke kun om at lave en form; det handler om at ramme dem stramt tolerances and achieving a perfect surface finish every single time, which is crucial for parts that fit and function flawlessly in your assemblies.

Nøgle ting at undersøge i en serviceudbyder 🤔

Ikke alle maskinforretninger er skabt ens. Her er hvad du skal spørge om:

1. Erfaring med jernmaterialer: Kan de håndtere forskellige kvaliteter af jern, som f.eks. Duktilt jern eller grå jern? Bearbejdningsmetoden kan variere.

2. Quality Control Processes: Do they have a solid system for checking parts during and after production? This is non-negotiable.

3. Communication and Support: Are they easy to talk to? You want a partner, not just a vendor. Quick responses to your technical queries make all the difference.

Hvorfor præcision betyder mere, end du måske tror

Det er nemt at se præcision som bare et tal på en tegning. Men i den virkelige verden betyder høj præcision, at dine dele passer sammen uden ekstra kraft, slides langsommere og udfører pålideligt. Mens det ofte siges, at strammere tolerancer altid fører til et bedre produkt, this might not be the full story for every application. Sometimes, pushing for an extremely tight tolerance drives up the cost without a real functional benefit. It's a balance. The exact relationship between tolerance, cost, and part lifespan in every single scenario is something we're still piecing together. However, for critical components, never compromise.

Min personlige tilgang til leverandørforholdet

Fra min erfaring kommer de bedste resultater fra at behandle din CNC-leverandør som en forlængelse af dit eget team. Jeg har fundet ud af, at butikker er villige til at diskutere design for manufacturability (DFM) early on—you know, suggesting a tiny change to a corner radius that makes the part much easier and cheaper to machine—are the ones that truly add value. It’s not just about receiving a quote; it's about a collaborative effort to get the best possible part at the most reasonable cost.

Almindelige forhindringer og hvordan man navigerer dem

Lad os være rigtige, problemer kan dukke op. Måske har et parti af dele en lille overflade ufuldkommenhed, eller en levering kører en dag bagefter. Nøglen er, hvordan leverandøren håndterer det. En gennemsigtig udbyder vil fortælle dig med det samme, forklare grundårsagen og præsentere en løsning. This proactive approach is a hallmark of a trustworthy partner. On the other hand, if you're always chasing them for updates, it might be a red flag.

Klar til at finde din ideelle partner?

Vi har gennemgået hvad, hvorfor og hvordan man vælger en precision iron CNC machining service. You're now equipped with the right questions to ask and the details to look for. The next step is to start a conversation with a provider who understands your specific needs and can deliver on their promises.

Har du et projekt i tankerne eller har brug for et direkte tilbud? Tøv ikke med at nå ud. Vores team er her for at hjælpe dig med at navigere i din indkøbsrejse. 👉 Connect with our online service team now to discuss your requirements!

Sådan vælges det rigtige værktøj til forskellige ståltyper i

Sådan vælges det rigtige værktøj til forskellige ståltyper i

Hvor nøjagtig kan CNC bearbejdning være? En praktisk guide t

Hvor nøjagtig kan CNC bearbejdning være? En praktisk guide t

Precision CNC bearbejdningsfremstilling: Hvad er det, og hvo

Precision CNC bearbejdningsfremstilling: Hvad er det, og hvo

Tilpasning af præcisions-CNC-aluminiumsdele: En guide til kv

Tilpasning af præcisions-CNC-aluminiumsdele: En guide til kv