Lang aluminiumsplade CNC bearbejdningsproces

Forståelse af lang aluminiumsplade CNC bearbejdning

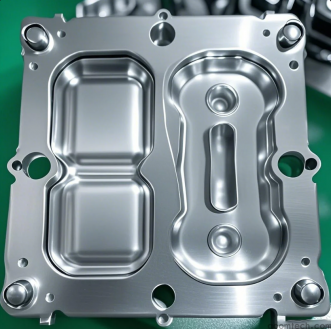

Lang aluminiumsplade CNC bearbejdning refererer til den computerstyrede subtraktive fremstillingsproces, der anvendes på aluminiumsplader med betydelige længdedimensioner (typisk over 1 meter). Denne specialiserede proces kræver avanceret udstyr, præcise værktøjsstrategier og ekspertprogrammering for at opretholde dimensionel nøjagtighed på tværs af hele emnet.

Nøgleprocesovervejelser

1. Material Selection: Vi arbejder med forskellige aluminiumlegeringer (6061, 7075, 5052) baseret på applikationskrav

2. Fixturing Solutions: Tilpasningsjigs og vakuumbord sikrer stabilitet under bearbejdning

3. Toolpath Optimization: Specialiseret programmering forhindrer værktøjssvingning i langstrakte snit

4. Thermal Management: Kontrollerede bearbejdningsparametre forhindrer varmeinduceret forvrængning

Hvorfor vælge AOOM til dit projekt?

Vores CNC machining facilitet har følgende egenskaber:

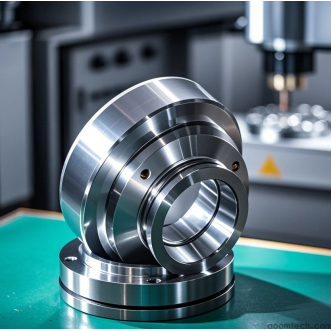

- Large - format CNC - fræsmaskiner med 5 - akseevner

- Højhastighedssindler (op til 24,000 RPM) for overlegne overfladefinish

- Avanceret inspectionsudstyr, herunder CMM'er

- ISO 9001 - certificeret kvalitetsmanagementsystem

Anvendelser på tværs af brancher

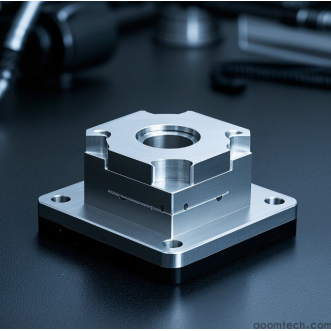

Denne proces er ideel til fremstilling:

- Aerospace structural components

- Semiconductor equipment frames

- Automotive prototyping parts

- Industrial automation system rails

Til din næste long aluminum plate projekt, kontakt AOOM Technology på www.aoomtech.com for at diskutere dine specifikke krav og modtage et konkurrencedygtigt tilbud.

Sådan finder du en pålidelig partner til højpræcisionsbliste

Sådan finder du en pålidelig partner til højpræcisionsbliste

Din guide til tilpasningstjenester til præcisionshardware CN

Din guide til tilpasningstjenester til præcisionshardware CN

Hvor meget koster CNC-bearbejdning med små partier til bruge

Hvor meget koster CNC-bearbejdning med små partier til bruge

En praktisk guide til CNC-bearbejdning med lille batch: Omko

En praktisk guide til CNC-bearbejdning med lille batch: Omko