CNC stor del bearbejdning

Forståelse af CNC stor del bearbejdning

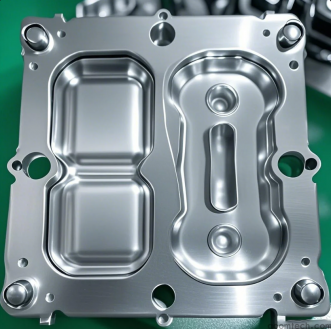

CNC stor del bearbejdning refererer til fremstilling af komponenter, der typisk overstiger 1 meter i enhver dimension, og som kræver specialudstyr og ekspertise. Hos AOOM bruger vi portalmøller og vandrette bearbejdningscentre med arbejdskonvolutter op til 5m × 3m × 2m til at håndtere sådanne projekter.

Nøgleudfordringer i stor del bearbejdning

1. Material Stability: Større metaldele er udsatte for termisk deformation under bearbejdning

2. Tool Path Optimization: Kræver avanceret CAM - programmering for at opretholde præcision

3. Vibration Control: Vores maskiner er udstyret med aktive dæmpningssystemer for overlegen overfladefinish

AOOMs tekniske fordele

Vores facilitet har:

- 5 - axis simultaneous machining evne for komplekse geometrier

- On - machine inspection med lasertrackere

- Temperature - controlled workshop (±1°C) for termisk stabilitet

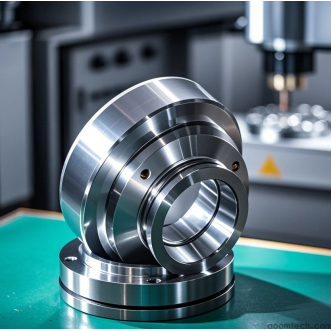

- Streng kvalitetskontrolproces inklusive CMM - verificering

Industrielle applikationer

Vi producerer jævnligt:

- Aerospace structural components

- Energy sector turbine housings

- Industrial machinery bases and frames

- Transportation equipment large assemblies

Hvorfor vælge AOOM til dine store behov

Med 15+ års erfaring i CNC machining tilbyder vi:

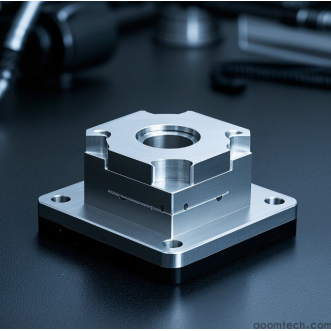

1. One - stop solution from design to finished product

2. Tight tolerances (±.05mm opnåeligt)

3. Material expertise including aluminum, steel, and titanium alloys

4. ISO 9001 certified quality management

Kontakt vores ingeniørhold på AOOM Technology for at diskutere dine krav til store skala bearbejdnings projekter og modtag et tilpasset løsningsforslag.

Sådan finder du en pålidelig partner til højpræcisionsbliste

Sådan finder du en pålidelig partner til højpræcisionsbliste

Din guide til tilpasningstjenester til præcisionshardware CN

Din guide til tilpasningstjenester til præcisionshardware CN

Hvor meget koster CNC-bearbejdning med små partier til bruge

Hvor meget koster CNC-bearbejdning med små partier til bruge

En praktisk guide til CNC-bearbejdning med lille batch: Omko

En praktisk guide til CNC-bearbejdning med lille batch: Omko