Hvilken tolerance kan du opnå med CNC Bar Machining? En praktisk guide

Hej der, ingeniører og professionelle indkøb! 👋 Har du nogensinde fundet dig selv stirrer på en teknisk tegning og spekulerer på, om din CNC-bjælkebearbejdningsleverandør kan actually hit those tiny tolerance numbers? You're not alone. I've been in those meetings where everyone nods, but deep down, there's that nagging question: "What's realistically achievable?" Let's cut through the marketing fluff and talk real numbers. 🤔

Så hvad er den virkelige aftale med CNC Bar Machining nøjagtighed?

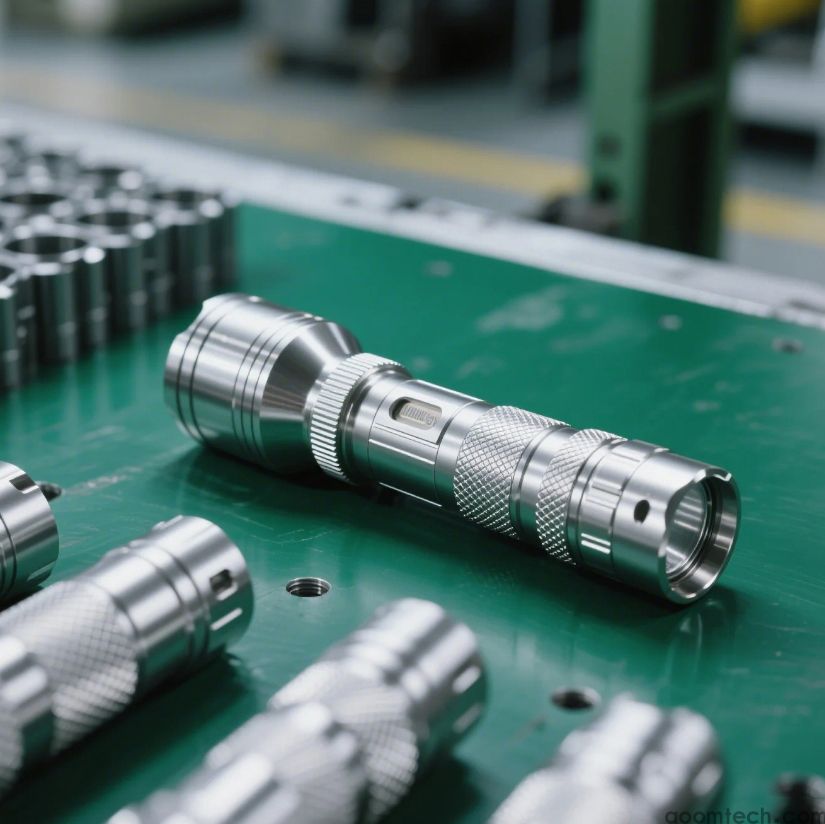

Første ting først, lad os besvare det store spørgsmål. For de fleste standard CNC-bjælkebearbejdningsjob kan du generelt forvente at holde tolerancer rundt ±.025 mm to ±.05 mm (±.001" to ±.002"). That's about the thickness of a human hair! But—and this is a big but—this isn't a guarantee for every single part. It depends on a whole bunch of factors that we'll dig into next. I've seen shops consistently hit these numbers on aluminum and brass, but when it comes to some tricky plastics or super-alloys, the story can change.

Hvilke faktorer faktisk rod med din maskinpræcision?

Det handler aldrig kun om maskinen. Her er de sædvanlige mistænkte, der kan gøre eller bryde dine tolerancemål:

✅ The Material Itself: Some materials are just easier to work with. Aluminum is pretty forgiving and stable, making it a dream for tight tolerances. But something like stainless steel? It can be a bit of a diva, moving around with heat and stress. The exact way different alloys behave under the cutting tool is something I'm still wrapping my head around.

✅ Machine Condition and Age: A brand-new, high-end Swiss-type lathe is a precision beast. An older, worn-out machine might struggle. It's that simple.

✅ The Length of the Part: This is a big one that often gets overlooked. Trying to hold a tight tolerance on a long, skinny bar? That's much harder than on a short, stubby part. Vibration and deflection become your enemies.

Hvordan kan du hjælpe din leverandør med at ramme disse strammere tolerancer?

Tro det eller ej, du har også en rolle at spille! Sådan kan du indstille dit projekt til succes:

🔧 Be Smart with Your Tolerances: Don't just call out super tight tolerances everywhere on the drawing. I always ask my team, "Does this surface really need to be that precise?" Only apply tight tolerances to critical features. This saves cost and headache.

🔧 Talk to Your Machinist Early: Get their input during the design phase. They might suggest a small change that makes the part much easier and cheaper to machine accurately.

🔧 Choose the Right Material: If high precision is your goal, maybe an aluminum grade is a better bet than that specific stainless steel you had in mind. Discuss the options.

Er "mere præcision" altid det rigtige svar?

Her er mine to cent fra at se hundreder af projekter. At jagte den absolut strammeste tolerance er ofte en fælde. 🤯 Omkostningerne stiger ikke lineært; det går op som en hockeystick. Den sidste .01 mm præcision kan fordoble din delpris. Du er nødt til at spørge: What does the function of the part actually require? Sometimes, "good enough" is not just good enough—it's the smartest business decision. Perfection can be the enemy of profitability.

Når det er sagt, for kritiske komponenter i luftfart eller medicinsk udstyr, er den ekstreme præcision ikke omsættelig. Men for mange generelle applikationer er det måske overkill. Den virkelige færdighed er at kende forskellen.

Fra min erfaring kommer de bedste resultater fra et partnerskab. Det handler ikke kun om at skubbe en leverandør til den laveste pris og den højeste præcision. Det handler om klar kommunikation, realistiske forventninger og forståelse af kompromiserne. Jeg har fundet ud af, at det at være på forhånd om dit budget og præstationsbehov fører til en meget jævnere proces og et bedre slutprodukt. 🚀 Bare noget at tænke på til dit næste projekt.

En praktisk guide til CNC-bearbejdning med lille batch: Omko

En praktisk guide til CNC-bearbejdning med lille batch: Omko

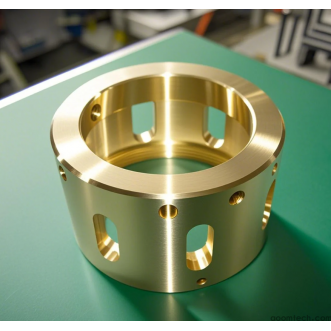

Præcision CNC bearbejdning til store kobberdele: En omfatten

Præcision CNC bearbejdning til store kobberdele: En omfatten

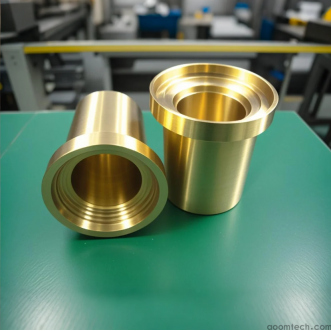

Hvilken tolerance kan du opnå med CNC messingbearbejdning? E

Hvilken tolerance kan du opnå med CNC messingbearbejdning? E

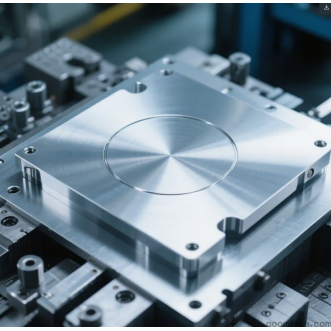

Hvad skal man kigge efter i et stort CNC-bearbejdningscenter

Hvad skal man kigge efter i et stort CNC-bearbejdningscenter