Ikke-standard CNC præcision bearbejdning tilpasning

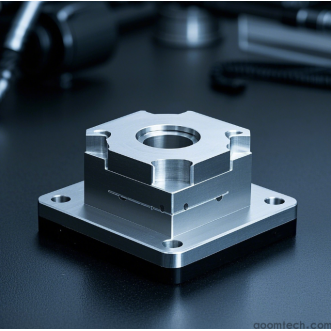

i moderne produktion, non-standard CNC precision machining customization plays a critical role in meeting unique industrial requirements. As a professional CNC machining service provider, AOOM Technology specializes in delivering high-quality, tailored solutions for complex and specialized components.

Hvad er ikke-standard CNC præcision bearbejdning tilpasning?

Ikke-standard CNC-præcisionsbearbejdning henviser til processen med fremstilling af dele, der ikke er i overensstemmelse med standardspecifikationer eller dimensioner. Dette custom machining approach is essential when clients require unique geometries, special materials, or complex features that standard off-the-shelf components cannot provide.

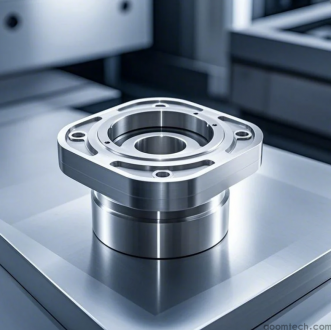

Nøglefordele ved at vælge AOOM til dine brugerdefinerede behov

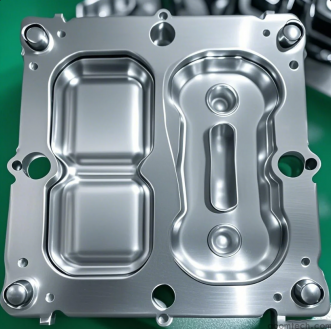

1. Advanced Equipment: Our facility houses state-of-the-art 5-axis CNC machines capable of handling the most complex geometries.

2. Material Expertise: We work with a wide range of materials including aluminum, stainless steel, titanium, and engineering plastics.

3. Precision Guarantee: Tight tolerances up to ±.001mm ensure your custom parts meet exact specifications.

4. End-to-End Service: From design consultation to final inspection, we provide comprehensive precision machining solutions.

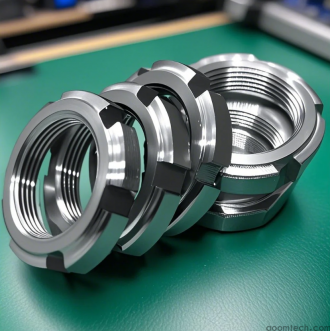

Anvendelser af ikke-standard CNC bearbejdede dele

Vores brugerdefinerede CNC-bearbejdningstjenester tjener forskellige brancher, herunder:

- Aerospace: Specialized components with strict weight and performance requirements

- Medical: Precision instruments and implantable devices

- Automotive: Prototype parts and low-volume production

- Robotics: Complex movement mechanisms and custom fittings

Hvorfor samarbejde med AOOM Technology?

Med mange års erfaring i non-standard CNC machining, AOOM Technology has established itself as a trusted partner for custom manufacturing solutions. Our team of skilled engineers works closely with clients to understand their specific needs and deliver components that exceed expectations in quality, precision, and performance.