CNC bearbejdningssonde: Præcisionsmåling til fejlfri produktion

I moderne CNC-bearbejdning kræver opnåelse af nøjagtighed på mikronniveau mere end bare avancerede maskiner - det kræver pålidelige måleværktøjer som CNC machining probes. As a professional CNC service provider, AOOM Technology explains how this critical tool elevates your manufacturing quality.

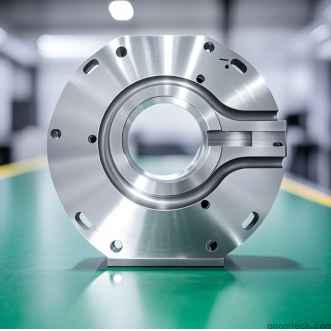

Hvad er en CNC Machining Probe?

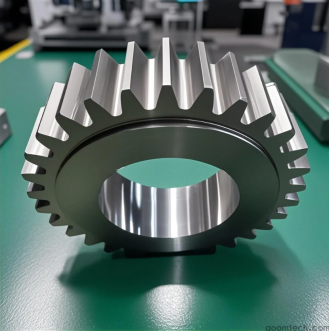

A CNC machining probe is a high-precision touch-trigger measurement device installed on CNC machines. It performs in-process inspection by contacting workpiece surfaces and transmitting positional data to the machine control system, enabling real-time compensation for tool wear or material variations.

Nøgleapplikationer inden for præcisionsfremstilling

1. Workpiece Alignment: Automatically establishes part zero points with .001mm repeatability

2. Tool Setting: Measures tool length/diameter offsets for optimal cutting parameters

3. In-Process Inspection: Verifies critical dimensions without removing parts

4. Batch Compensation: Adjusts machining programs based on first-article measurements

Hvorfor vælge AOOMs sondeudstyrede CNC-tjenester?

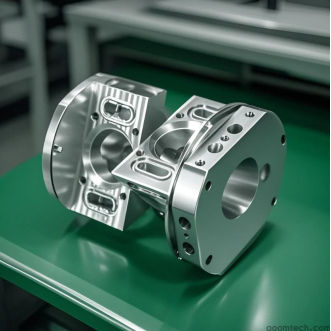

Vores CNC machining centers integrate Renishaw probing systems to deliver:

• 30% reduction in setup time through automated alignment

• .005mm measurement accuracy for aerospace-grade parts

• Seamless integration with our ISO 9001-certified quality system

• Comprehensive probe data reporting for full traceability

Fra prototypevalidering til produktion i høj volumen sikrer AOOM Technologys sondeforbedrede CNC-løsninger, at dine dele opfylder de strammeste tolerancer. Contact our engineering team to discuss your project's specific measurement requirements.