CNC Rulleakselbearbejdning: Præcisionsløsninger til industrielle applikationer

i moderne produktion, CNC roller shaft machining plays a pivotal role in ensuring the accuracy and durability of rotating components across industries. As a specialized CNC machining service provider, AOOM Technologies delivers tailored solutions for high-performance roller shafts used in printing, packaging, steel mills, and conveyor systems.

Hvad er CNC Roller Shaft Machining?

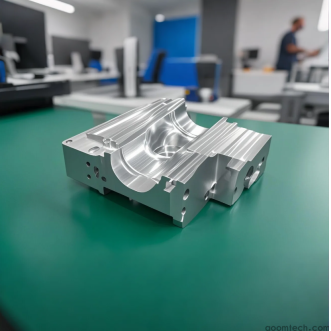

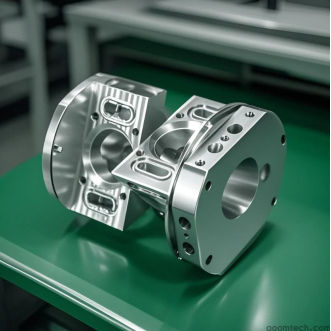

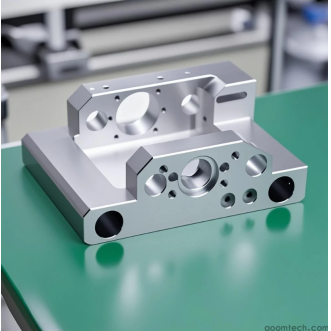

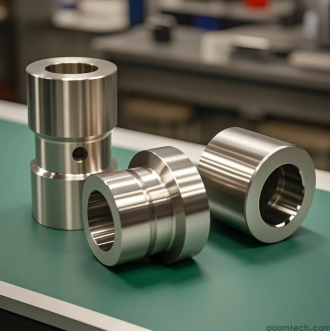

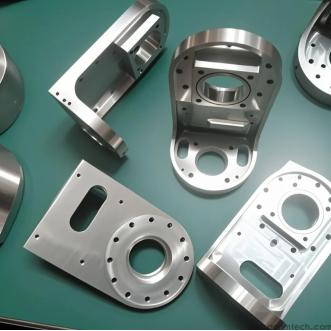

Denne proces involverer computerstyrede skæreværktøjer til at forme metalbillets til præcisions rullekakter med stramme tolerancer (typisk ± 0,005 mm). Vores 5-akse CNC machining centers handle materials ranging from alloy steels to stainless steels and aluminum alloys, creating components with superior surface finishes (Ra .4μm achievable).

Nøglefordele ved vores CNC Roller Shaft Services

1. Material Expertise: We machine EN8, EN19, 414, and 17-4PH stainless steel shafts with heat treatment options

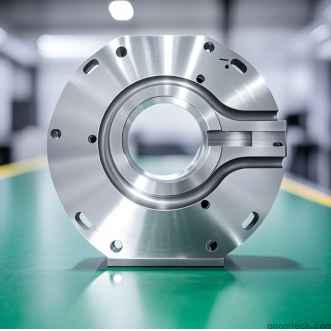

2. Precision Grinding: Cylindrical grinding ensures ≤.01mm runout tolerance

3. Surface Treatments: Chrome plating, nitride hardening, or ceramic coatings available

4. Customization: Flanges, keyways, and threaded ends machined to OEM specifications

Branchespecifikke løsninger

Vores CNC roller shaft applications include:

- Printing press cylinders with dynamic balancing

- Paper machine dryer rolls with steam passage machining

- Conveyor drive shafts with spline or gear profiles

- Textile machinery rollers with polished surfaces

Hvorfor vælge AOOM teknologier?

Med ISO 9001-certificerede faciliteter i Kina kombinerer vi 15+ års erfaring med CNC-bearbejdning med:

✔ 50+ CNC turning/milling centers (including Swiss-type lathes)

✔ CMM inspection and full dimensional reporting

✔ Just-in-time delivery capabilities

✔ Engineering support for DFM optimization

Anmod om et tilbud på dit rulleakselprojekt i dag på www.aoomtech.com, where precision meets industrial reliability.