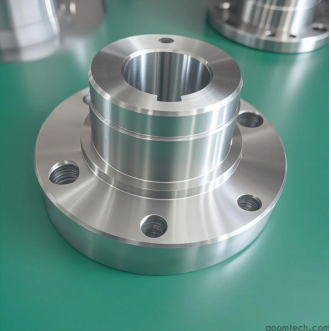

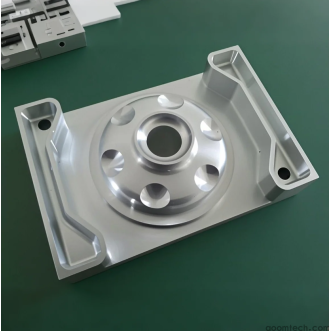

CNC bearbejdning rustfrit stål flanger

Flanger i rustfrit stål er vigtige komponenter i rørsystemer, der tilbyder holdbarhed og korrosionsbestandighed. CNC machining ensures these flanges meet precise dimensional tolerances and surface finish requirements. At AOOM, we specialize in high-precision CNC machining of stainless steel flanges, delivering customized solutions for industries like oil & gas, chemical processing, and aerospace.

Hvorfor vælge CNC bearbejdning til rustfrit stål flanger?

1. Precision Engineering: CNC-teknologi opnår stramme tolerancer (± .01mm) for flangefladhed, bolthuljustering og tætningsoverflader.

2. Material Versatility: We machine ASTM A182 (304/316), duplex, and super-austenitic stainless steels.

3. Efficiency: Automated toolpaths reduce production time while minimizing material waste.

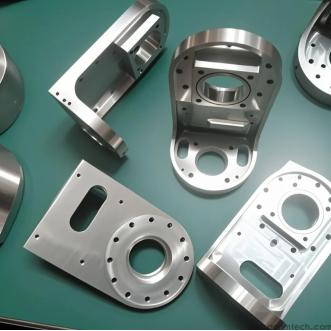

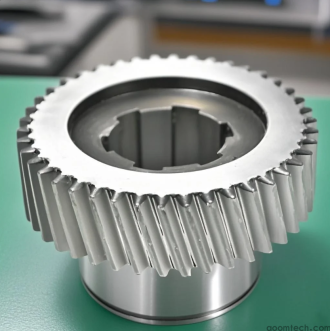

Nøgleprocesser i CNC-bearbejdningsflanger

- Drejning: Til ydre diameter (OD) og ansigtsbearbejdning.

Drilling/Tapping: Accurate bolt hole patterns via CNC-controlled indexing.

Milling: Complex profiles (e.g., raised face, RTJ grooves) with 5-axis capabilities.

AOOMs fordele i CNC machining of stainless steel flanges

ISO 9001-certificeret kvalitetskontrol med 3D-scanning.

Prototype to bulk production (up to 10,000 units/month).

Competitive pricing with DFM (Design for Manufacturing) feedback.

Kontakt AOOM på www.aoomtech.com for your stainless steel flange needs, combining CNC precision with industry-leading expertise.