CNC bearbejdning transportørbordskomponenter

I moderne industriproduktion, CNC machining conveyor table components play a critical role in ensuring efficient material handling and precision production. As a leading CNC machining service provider, AOOM Technology specializes in manufacturing high-performance conveyor system parts that meet the most demanding industrial requirements.

Hvad er CNC bearbejdede transportbordskomponenter?

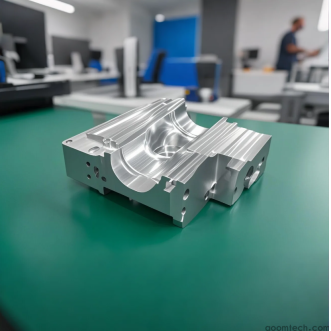

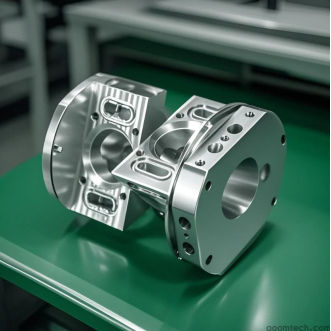

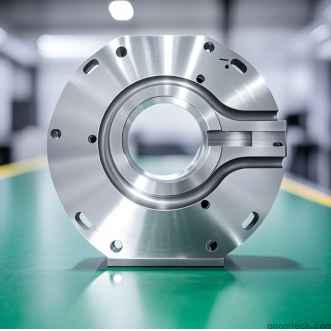

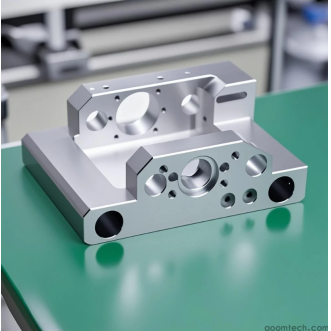

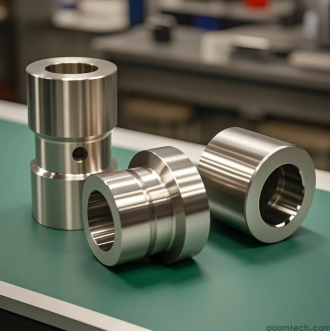

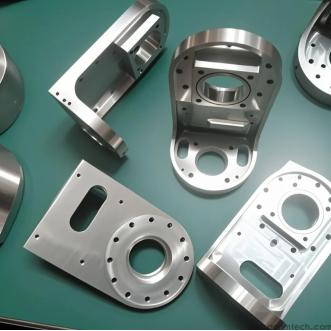

Disse henviser til precision-engineered dele, der anvendes i transportsystemer, herunder styreskinner, monteringsbeslag, drivmekanismer og støttestrukturer. I modsætning til konventionelle fabrikationsmetoder, CNC machining ensures dimensional accuracy within ±.01mm, essential for smooth conveyor operation and minimal downtime.

Nøglefordele ved vores CNC bearbejdede komponenter

1. Superior Material Selection: We work with aircraft-grade aluminum, stainless steel, and engineering plastics to match your specific load-bearing and environmental needs.

2. Customized Solutions: Our engineers can adapt designs for unique conveyor configurations, including curved paths or heavy-duty applications.

3. Surface Treatment Options: Anodizing, powder coating, or electropolishing available to enhance durability and corrosion resistance.

Tekniske evner hos AOOM Technology

Vores 5-aksede CNC-maskiner og schweiziske drejebænke producerer transportkomponenter med komplekse geometrier, som traditionelle metoder ikke kan opnå. For dele med høj slid som kædestyrer eller rullestøtter implementerer vi hardened steel machining with HRC 50+ hardness while maintaining tight tolerances.

Med ISO 9001-certificeret kvalitetskontrol garanterer AOOM, at hver transportkomponent opfylder dine specifikationer. Kontakt vores ingeniørteam i dag for at diskutere dine projektkrav og modtage et konkurrencedygtigt tilbud inden for 24 timer.