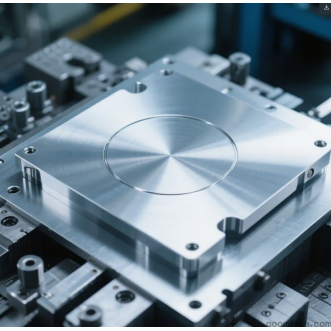

CNC-Bearbeitung von Aluminiumplatten: Kostenfaktoren und Präzisionslösungen

Wenn es um die Beschaffung von CNC - Bearbeitungsdienstleistungen für Aluminiumbleche geht, ist das Verständnis der Preisvariablen für Einkaufsmanager und Ingenieure von entscheidender Wichtigkeit. Als professioneller Anbieter von CNC - Bearbeitungsdienstleistungen liefert AOOM Technology transparente Koststrukturen und hält dabei ISO - zertifizierte Qualitätsstandards ein.

Schlüsselfaktoren, die die Kosten für die CNC - Bearbeitung von Aluminium beeinflussen

1. Materialstufe: 6061 im Vergleich zu 7075 Aluminiumlegierungen unterscheiden sich erheblich in der Bearbeitbarkeit und den Rohmaterialkosten. 2. Teilkomplexität: Mehrachsige Bearbeitungsanforderungen erhöhen die Programmier- und Zykluszeiten. 3. Oberflächenbehandlung: Zusätzliche Prozesse wie Anodisieren oder Pulverbeschichten erhöhen die Nachbearbeitungskosten. 4. Bestellmenge: Großbestellungen profitieren typischerweise von Kosteneinsparungen durch Skaleneffekte.

Die Wettbewerbsvorteile von AOOM bei der Aluminiumbearbeitung

Unsere CNC - Bearbeitungsanlage verfügt über:

- 5 - Achsen - Fräszentren für komplexe Geometrien - ± 0,005mm Toleranzfähigkeiten - Eigenes Qualitätskontrolllabor - Design - for - Manufacturing - Beratungsdienstleistungen (DFM)

Optimierung Ihres Projektbudgets

Kosteneffizienten CNC - Bearbeitung von Aluminiumblechen erreichen:

1. Vereinigung mehrerer Teile in einem einzigen Setup 2. Standardisierung von Toleranzen, soweit möglich 3. Überlegung von Prototypchargen vor der vollständigen Produktion 4. Nutzung unseres Netzwerks für die Materialbeschaffung

Fordern Sie ein individuelles Angebot über unsere Website auf aoomtech.com, einschließlich Ihrer CAD - Dateien und Spezifikationen für eine genaue Preisermittlung. Unser Ingenieurteam bietet kostenlose Vorschläge zur Designoptimierung, um die Kosten zu reduzieren, ohne die Funktionalität zu beeinträchtigen.

Ein praktischer Leitfaden für die Kleinserien-CNC-Bearbeitun

Ein praktischer Leitfaden für die Kleinserien-CNC-Bearbeitun

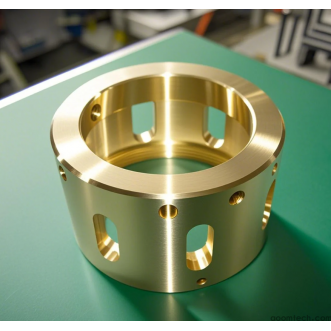

Präzisions-CNC-Bearbeitung für große Kupferteile: Eine umfas

Präzisions-CNC-Bearbeitung für große Kupferteile: Eine umfas

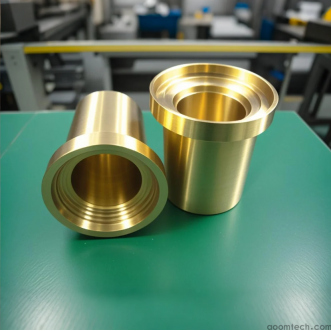

Was Toleranz können Sie mit CNC-Messingbearbeitung erreichen

Was Toleranz können Sie mit CNC-Messingbearbeitung erreichen

Was in einem großen CNC-Bearbeitungszentrum für Auftragsarbe

Was in einem großen CNC-Bearbeitungszentrum für Auftragsarbe