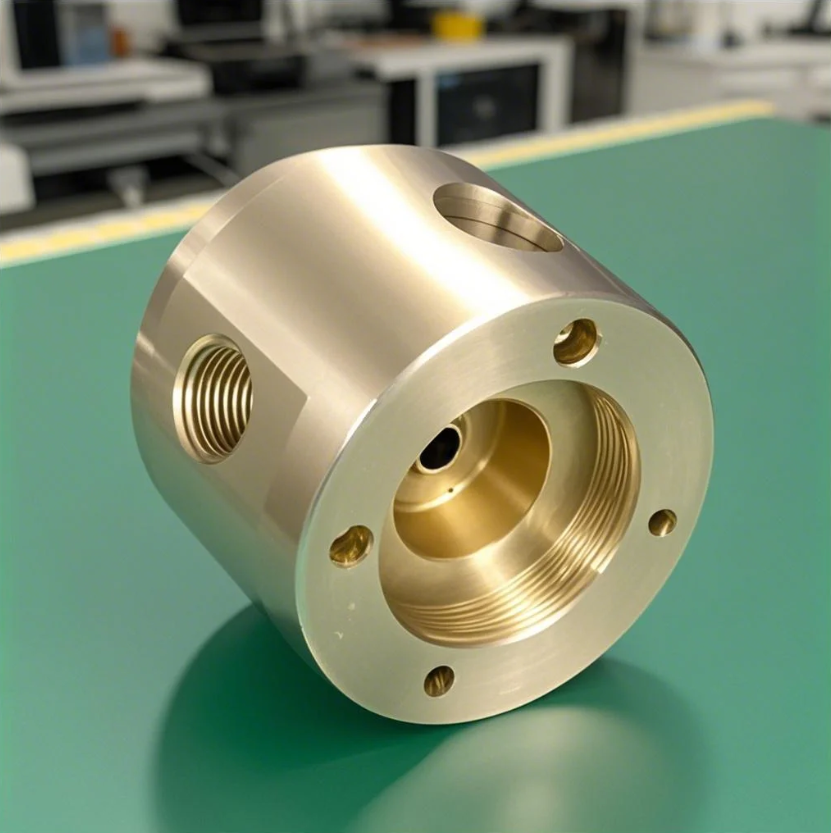

CNC-Bearbeitung aus Messing: Präzisionsfertigung für langlebige Komponenten

Wenn es um brass CNC machining, manufacturers demand a combination of precision, material expertise, and cost-efficiency. At AOOM, we specialize in transforming brass alloys into high-performance components for industries ranging from plumbing to aerospace. This guide explores the technical nuances of brass machining and how our capabilities deliver unmatched results.

Warum Messing für die CNC-Bearbeitung wählen?

Messing (eine Legierung aus Kupfer und Zink) bietet außergewöhnliche Bearbeitbarkeit, Korrosionsbeständigkeit und elektrische Leitfähigkeit. Seine selbstschmierenden Eigenschaften reduzieren den Werkzeugverschleiß während CNC machining, making it ideal for valves, fittings, and decorative hardware. Our ISO 9001-certified facility optimizes feed rates and tool paths specifically for brass to prevent material galling.

AOOMs CNC-Bearbeitungsprozess aus Messing

1. Material Selection: We stock C36000 (free-cutting brass), C26000 (cartridge brass), and other grades to match your project requirements.

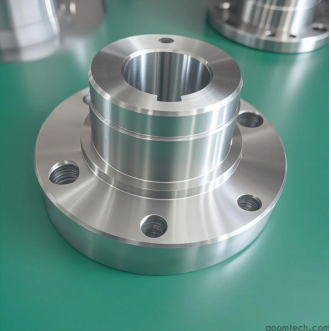

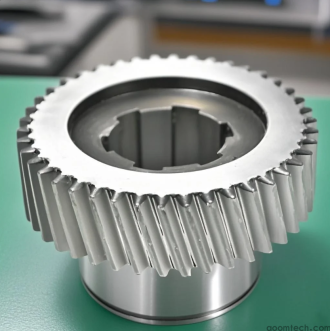

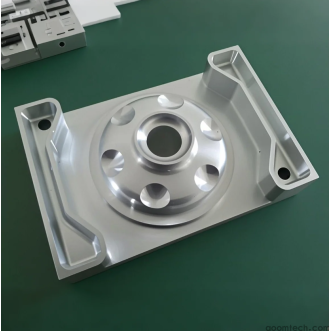

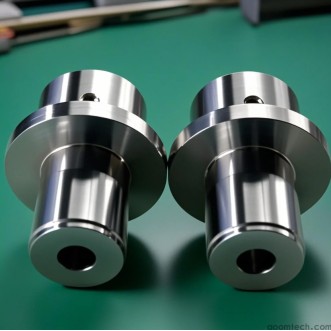

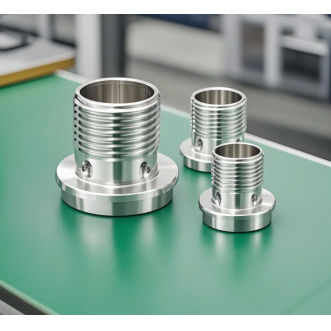

2. Precision Turning/Milling: 5-axis CNC machines achieve ±.005mm tolerances with mirror-like surface finishes.

3. Secondary Processing: Deburring, polishing, or plating (nickel/chrome) services available.

Branchen, die wir mit Messingkomponenten bedienen

• Electronics: RF connectors, terminals (benefiting from brass's EMI shielding)

• Automotive: Fuel system components, bushings

• Architecture: Custom decorative fixtures with intricate detailing

Im Gegensatz zu generischen CNC machining suppliers, AOOM provides DFM feedback to optimize your brass part designs for manufacturability and cost reduction. Our 24/7 production capacity and strict QC protocols ensure on-time delivery of defect-free components.