¿Cuál es la precisión de mecanizado general del CNC?

Como proveedor profesional de servicios de mecanizado CNC, AOOM Technology entiende que la precisión es un factor crítico para ingenieros, gerentes de adquisiciones y dueños de empresas al seleccionar soluciones de mecanizado. Este artículo explora la precisión de mecanizado general que se puede lograr con la tecnología CNC y cómo AOOM asegura resultados de primer nivel para sus proyectos.

Comprender la precisión del mecanizado CNC

La precisión estándar de la maquinaria CNC generalmente varía entre ±.005 mm y ±.1 mm (±.0002" a ±.004"), dependiendo de múltiples factores, incluyendo el tipo de máquina, las propiedades del material, la herramienta y el control del proceso. Las máquinas CNC de alta gama pueden alcanzar tolerancias aún más estrechas, hasta ±.001 mm (±.00004") para aplicaciones especializadas.

Factores Clave Que Afectan La Precisión CNC

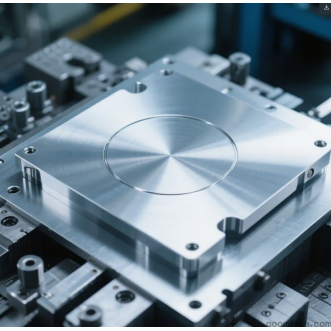

1. Calidad de la máquina: Nuestra instalación certificada por ISO utiliza fresadoras CNC de 5 ejes avanzadas y tornos tipo suizo con construcciones rígidas y sistemas de compensación térmica.

2. Selección de herramientas: AOOM emplea brocas finales de carburo de alta calidad y herramientas con puntas de diamante para una resistencia al desgaste excepcional.

3. Características del material: Diferentes materiales (aluminio, titanio, plásticos) requieren estrategias de mecanizado específicas para mantener la estabilidad dimensional.

4. Ingeniería del proceso: Nuestros técnicos optimizan los parámetros de corte, la fijación y las trayectorias de herramientas para cada proyecto.

Las capacidades de precisión de AOOM

En AOOM Technology (https://www.aoomtech.com/), entregamos constantemente piezas con:

- Tolerancia estándar: ±.02 mm (±.0008")

- Tolerancia de alta precisión: ±.005 mm (±.0002")

- Tolerancia de ultra-precisión: Sujeta a solicitud con equipo especializado

Nuestros servicios de mecanizado CNC incorporan equipos de metrología avanzados, incluyendo CMMs y comparadores ópticos, para verificar cada dimensión según sus especificaciones. Mantenemos procedimientos rigurosos de control de calidad para asegurar una precisión repetible en las series de producción.

Aplicaciones del mecanizado CNC de precisión

Desde componentes aeroespaciales que requieren precisión a nivel de micras hasta dispositivos médicos con geometrías complejas, nuestras capacidades apoyan a industrias donde la precisión no es negociable. Póngase en contacto con AOOM Technology hoy para discutir cómo podemos cumplir con sus requisitos de tolerancia específicos mientras optimizamos la eficiencia de la producción.

Una guía práctica para el mecanizado CNC en lotes pequeños:

Una guía práctica para el mecanizado CNC en lotes pequeños:

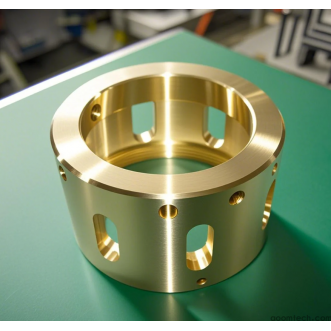

Mecanizado CNC de precisión para piezas grandes de cobre: un

Mecanizado CNC de precisión para piezas grandes de cobre: un

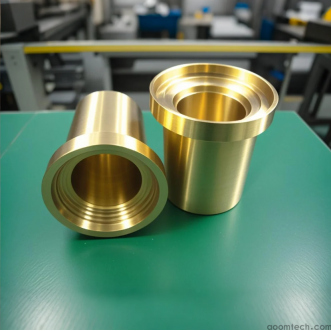

¿Qué Tolerancia Puedes Lograr con Mecanizado CNC de Latón? U

¿Qué Tolerancia Puedes Lograr con Mecanizado CNC de Latón? U

¿Qué buscar en un gran centro de mecanizado CNC para trabajo

¿Qué buscar en un gran centro de mecanizado CNC para trabajo