Proceso De Mecanizado De Pernos CNC

En la fabricación de precisión, el proceso de mecanizado de pernos CNC es una operación crítica para las industrias que requieren sujetadores de alta tolerancia. Como proveedor líder de servicios de mecanizado CNC, AOOM Technology ofrece soluciones excepcionales de fabricación de pernos adaptadas a las aplicaciones aeroespaciales, automotrices e industriales.

Comprensión del mecanizado de pernos CNC

El proceso de mecanizado de pernos CNC implica el uso de tornos o fresadoras controladas por computadora que transforman barras metálicas en bruto en pernos de precisión a través de operaciones secuenciales, como torneado, roscado, formación de la cabeza y acabado de superficie. Nuestras máquinas CNC de 5 ejes logran tolerancias de ±.005mm, lo que asegura un engranaje perfecto de las roscas y una distribución de carga adecuada.

Ventajas Clave De Nuestra Producción De Pernos CNC

1. Versatilidad de materiales: Mecanizamos pernos de acero inoxidable, titanio, aluminio y aleaciones exóticas

2. Precisión de rosca: Perfiles de rosca ACME, UN, métricos y personalizados con precisión certificada

3. Tratamientos de superficie: Placado, anodizado o pasivación opcionales para resistencia a la corrosión

4. Flexibilidad de lote: Desde cantidades de prototipo hasta series de producción de más de 100.000 unidades

Especificaciones Técnicas

Nuestro proceso de mecanizado de pernos CNC admite:

• Rango de diámetros: M1,6 a M64

• Relaciones longitud - diámetro de hasta 12:1

• Tipos de cabeza: Hexagonal, de casquillo, de flanco y diseños personalizados

• Cumplimiento de los estándares ISO 898, ASME B18.2 y DIN

¿Por qué elegir la tecnología AOOM?

Con más de 15 años de experiencia en mecanizado CNC, combinamos tornos avanzados de tipo suizo con un riguroso control de calidad (incluido el 100% de inspección de roscas) para entregar pernos con propiedades mecánicas perfectas. Nuestros ingenieros optimizan todos los parámetros de mecanizado, desde las velocidades de corte hasta las trayectorias de las herramientas, lo que garantiza la máxima resistencia a la tracción y la resistencia a la fatiga.

Solicite una revisión gratuita del proyecto en www.aoomtech.com para experimentar la fabricación de pernos de precisión que elimina los problemas de montaje y reduce los costos totales de los sujetadores.

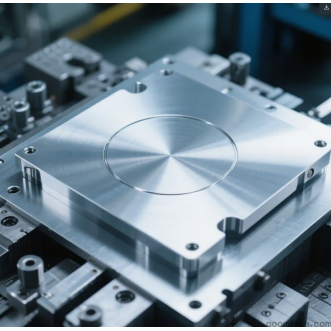

Una guía práctica para el mecanizado CNC en lotes pequeños:

Una guía práctica para el mecanizado CNC en lotes pequeños:

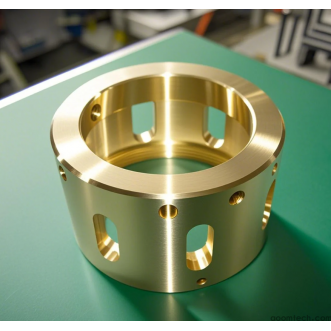

Mecanizado CNC de precisión para piezas grandes de cobre: un

Mecanizado CNC de precisión para piezas grandes de cobre: un

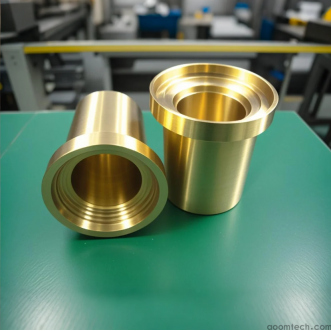

¿Qué Tolerancia Puedes Lograr con Mecanizado CNC de Latón? U

¿Qué Tolerancia Puedes Lograr con Mecanizado CNC de Latón? U

¿Qué buscar en un gran centro de mecanizado CNC para trabajo

¿Qué buscar en un gran centro de mecanizado CNC para trabajo