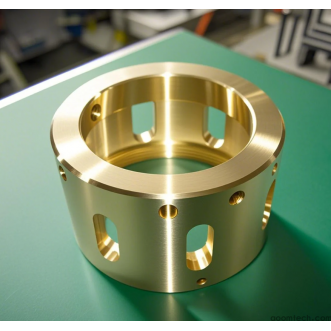

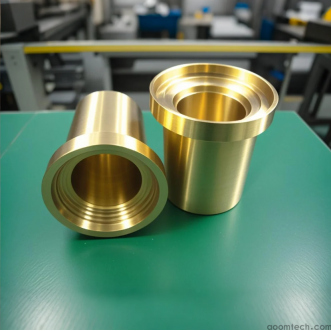

Proceso De Mecanizado CNC De Cobre: Técnicas Y Aplicaciones De Precisión

Comprensión del mecanizado CNC de cobre

El mecanizado CNC de cobre implica técnicas de fabricación sustractiva para dar forma a materiales de cobre en bruto en componentes precisos. Debido a la excelente conductividad y propiedades térmicas del cobre, requiere estrategias de mecanizado para mantener la precisión dimensional mientras se evita la deformación del material.

Pasos clave en el mecanizado CNC de cobre

1. Selección de materiales: Elegir la aleación de cobre adecuada (C10100, C11000, etc.) en función de la conductividad y los requisitos mecánicos.

2. Optimización de la trayectoria de la herramienta: Nuestros ingenieros programan trayectorias de herramientas para tener en cuenta la naturaleza pegajosa del cobre, reduciendo el desgaste de la herramienta.

3. Gestión del refrigerante: Implementar mecanizado controlado por temperatura para evitar el endurecimiento del trabajo.

4. Acabado de la superficie: Procesos opcionales como electropolido para mejorar la conductividad y la resistencia a la corrosión.

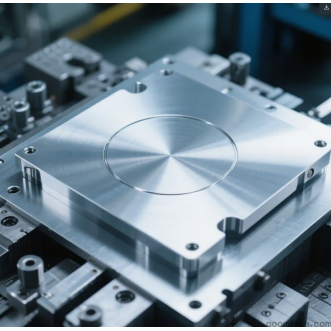

Ventajas Técnicas de AOOM

Con más de 15 años de experiencia, AOOM Technologies ofrece:

- Centros de mecanizado de cobre dedicados con husillos de alta velocidad (hasta 30.000 RPM)

- Laboratorio de metrología interno para control de calidad a nivel de micras

- Capacidades de prototipado a producción masiva

Visite nuestro sitio web para explorar estudios de casos de nuestras soluciones de CNC de cobre.

Aplicaciones En Todas Las Industrias

Nuestros componentes de cobre de precisión cumplen funciones críticas en:

• Barras colectoras eléctricas y conectores

• Intercambiadores de calor y sistemas de refrigeración

• Componentes de blindaje RF

• Sistemas eléctricos automotrices y aeroespaciales

Para obtener resultados óptimos en su próximo proyecto de CNC de cobre, contáctese con el equipo de ingeniería de AOOM para un análisis de DFM y una consulta técnica.

Una guía práctica para el mecanizado CNC en lotes pequeños:

Una guía práctica para el mecanizado CNC en lotes pequeños:

Mecanizado CNC de precisión para piezas grandes de cobre: un

Mecanizado CNC de precisión para piezas grandes de cobre: un

¿Qué Tolerancia Puedes Lograr con Mecanizado CNC de Latón? U

¿Qué Tolerancia Puedes Lograr con Mecanizado CNC de Latón? U

¿Qué buscar en un gran centro de mecanizado CNC para trabajo

¿Qué buscar en un gran centro de mecanizado CNC para trabajo