Cotización de mecanizado de precisión CNC

Factores que afectan la cotización del mecanizado CNC

1. Costos de materiales: El tipo de material prima (por ejemplo, aluminio, acero inoxidable, titanio) impacta significativamente el precio debido a los precios variables en el mercado y la maquinabilidad.

2. Complejidad de la pieza: Los diseños intrincados con tolerancias estrictas o paredes delgadas requieren herramientas avanzadas y un tiempo de mecanizado más largo.

3. Volumen de producción: Los pedidos en grandes cantidades a menudo reducen los costos unitarios a través de las economías de escala.

4. Acabado de superficie: Procesos adicionales (anodizado, pulido) aumentan la cotización total.

5. Plazo de entrega: Los pedidos urgentes pueden incurrir en tarifas de expedición.

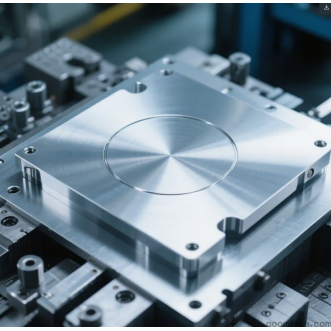

Cómo AOOM Optimiza Sus Costos De Mecanizado CNC

AOOM Technology aprovecha máquinas CNC avanzadas de 5 ejes y herramientas internas para minimizar el desperdicio y acelerar la producción. Nuestros ingenieros proporcionan retroalimentación de Diseño para la Fabricación (DFM) para simplificar la geometría de la pieza sin sacrificar la funcionalidad, reduciendo las horas de mecanizado y el uso de materiales.

Modelo de Precios Transparente

Ofrecemos cotizaciones instantáneas en línea para proyectos estándar a través de nuestra plataforma (www.aoomtech.com), con desgloses detallados para solicitudes personalizadas. A diferencia de los competidores, AOOM incluye los costos de post-procesamiento de antemano para evitar tarifas ocultas.

Para una cotización de mecanizado CNC personalizada, cargue sus archivos CAD en el sistema de cotizaciones de AOOM o póngase en contacto con nuestro equipo de ingeniería para soluciones de prototipado de alta variedad y bajo volumen.

Una guía práctica para el mecanizado CNC en lotes pequeños:

Una guía práctica para el mecanizado CNC en lotes pequeños:

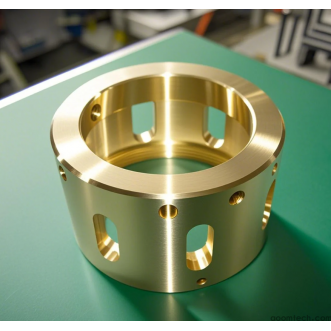

Mecanizado CNC de precisión para piezas grandes de cobre: un

Mecanizado CNC de precisión para piezas grandes de cobre: un

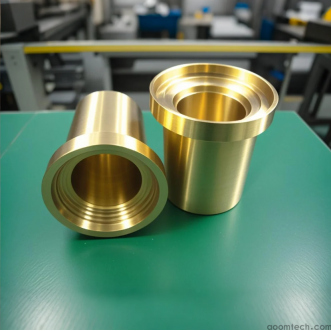

¿Qué Tolerancia Puedes Lograr con Mecanizado CNC de Latón? U

¿Qué Tolerancia Puedes Lograr con Mecanizado CNC de Latón? U

¿Qué buscar en un gran centro de mecanizado CNC para trabajo

¿Qué buscar en un gran centro de mecanizado CNC para trabajo