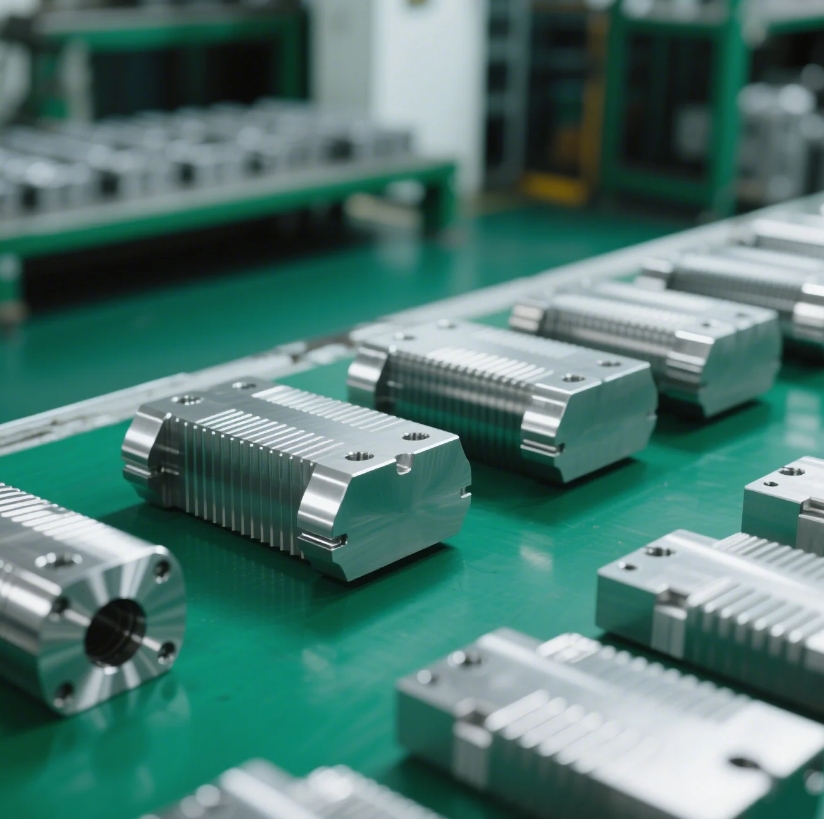

Precio De Mecanizado CNC: Factores, Cálculo Y Estrategias De Ahorro De Costos

Como profesional CNC machining service provider, AOOM Technology understands that pricing is a top concern for procurement managers and engineers. This article provides transparent insights into how CNC machining costs are determined and how to optimize your budget without compromising quality.

Factores Clave Que Afectan Los Precios Del Mecanizado CNC

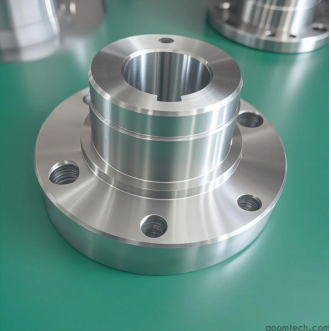

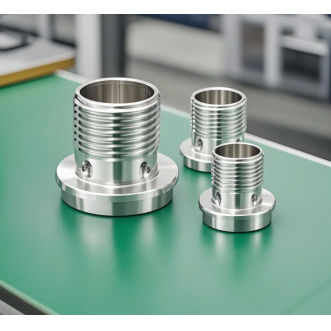

1. Material Costs: Aluminum, stainless steel, and titanium have significantly different price points

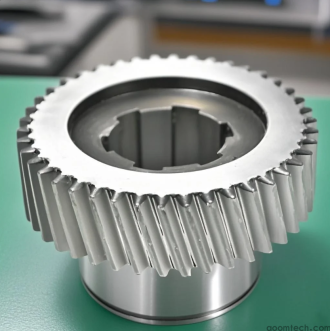

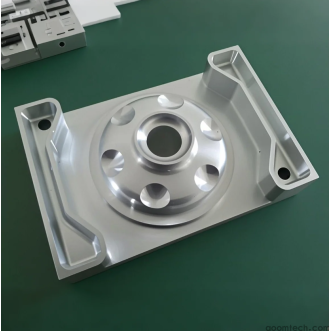

2. Part Complexity: Intricate geometries require more machining time and specialized tooling

3. Production Volume: Higher quantities typically reduce per-unit costs through economies of scale

4. Tolerance Requirements: Tight tolerances (±.001") demand precision equipment and additional QC steps

5. Surface Finishing: Secondary processes like anodizing or polishing add to the total cost

Nuestra Ventaja de Precios Competitivos en AOOM

Con máquinas avanzadas de 5 ejes y procesos de fabricación ajustados, ofrecemos:

- 15-20% lower costs than industry averages for medium-volume production

- Transparent quoting with detailed cost breakdowns

- Value engineering suggestions to reduce unnecessary expenses

- Bulk order discounts for long-term partners

Cómo obtener una cita precisa

Para precisión CNC machining price estimation, please provide:

1. CAD files (STEP or IGES format preferred)

2. Material specifications

3. Quantity requirements

4. Surface finish expectations

5. Delivery timeline

Nuestro equipo de ingeniería analizará su proyecto y responderá a con una cotización competitiva en 24 horas, junto con con comentarios de fabricación para reducir potencialmente sus costos.