CNC megmunkálás költségszámítás módszer

Szakmaiként CNC machining service provider, AOOM Technology understands that cost calculation is a critical concern for procurement managers and engineers. This guide will explain the key factors affecting CNC machining costs and how we optimize pricing at AOOM.

Kulcsfontosságú tényezők a CNC megmunkálás költségszámításában

1. Material Costs: Different metals (aluminum, steel, titanium) and plastics have varying raw material prices that directly impact the total cost.

2. Machine Time: Complex geometries requiring longer machining time increase costs. Our advanced 5-axis machines at AOOM reduce cycle times.

3. Labor Costs: Skilled technician time for programming, setup, and quality inspection.

4. Surface Finishing: Additional processes like anodizing or polishing add to the base CNC machining cost.

Az AOOM költségoptimalizálási megközelítése

• Design for Manufacturability: Our engineers review your designs to suggest cost-saving modifications without compromising functionality.

• Bulk Discounts: Higher quantities typically reduce per-unit costs through better material utilization and setup amortization.

• Advanced Tooling: Our modern CNC equipment achieves tighter tolerances with less material waste.

Átlátható árképzési struktúra

Az AOOM-nál részletes idézeteket biztosítunk az anyagköltségek, a gépidő, a befejezési folyamatok és bármilyen speciális követelmények lebontásával.Ez az átláthatóság segít ügyfeleinknek megalapozott döntéseket hozni CNC machining projects.

Lépjen kapcsolatba az AOOM Technology-val ma egy ingyenes projektértékeléshez és költségbecsléshez az Ön konkrét követelményeihez.

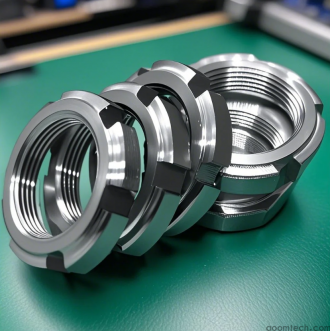

CNC nagy pontosságú alkatrészek feldolgozása

CNC nagy pontosságú alkatrészek feldolgozása

CNC megmunkálás költségszámítás módszer

CNC megmunkálás költségszámítás módszer

CNC megmunkálás egyedi mechanikus alkatrészek gyártója

CNC megmunkálás egyedi mechanikus alkatrészek gyártója

CNC rozsdamentes acél megmunkálás idézet: az árképzést befol

CNC rozsdamentes acél megmunkálás idézet: az árképzést befol