CNC megmunkáló gomb: Precíziós gyártási megoldások

A világában CNC megmunkálásakor, minden alkatrész igényli a részletes figyelmet - különösen olyan működő alkatrészek, mint a gombok. Az AOOM-ban specializálódunk a nagy pontosságú CNC megmunkált gomb megoldások szállításában, amelyek megfelelnek azoknak az iparágoknak a követelményeinek, amelyek megbízhatóságot és tartóságot igényelnek.

Mi az a CNC megmunkáló gomb?

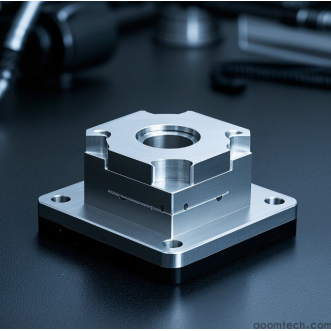

A CNC megmunkált gomb utal egy vezérlőfelületi összetevőhöz, amelyet a számítógépes numerikus vezérlés (CNC) technológiával gyártanak. Ezek a gombok létfontosságúak olyan alkalmazásokban, amelyek terjednek az ipari gépektől a fogyasztói elektronikáig, ahol a pontos tűrések és a sima működés nem tárgyalható.

A CNC megmunkált gombok legfontosabb előnyei

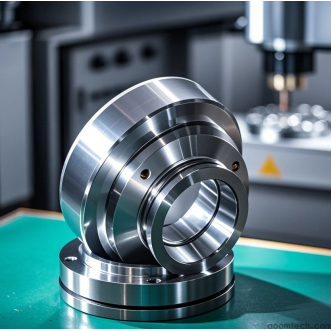

1. Anyagváltozatosság: Dolgozunk fémekkel (alumínium, rozsdamentes acél, sárgarézet) és mérnöki műanyagokkal, hogy kielégítsük a különböző működési követelményeket.

2. Pontos mérnöki munkák: Szűk tűrések (±.01mm) biztosítják a következetes teljesítményt és a zökkenőmentes integrációt.

3. Egyedi szabás: A gombok specifikus textúrákkal, ergonomikus profilokkal vagy márkacsempészkedéssel is kialakíthatók.

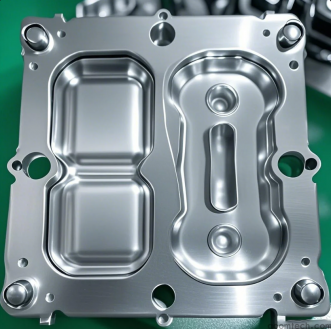

Az AOOM gyártási folyamata

A mi 5 - tengelyes CNC marás és svájci forgatás képességeink lehetővé teszik az összetett geometriákat és a nagy mennyiségű gyártást. Minden gomb átesik a szigorú minőségellenőrzéseken, beleértve a felületi befejezési elemzést és a működési tesztelést.

Miért válasszon AOOM a CNC gombokhoz?

• Iparági szakértelme: 10+ évnyi tapasztalat az űrhajózásban, a gyógyszerészetben és az autóiparban.

• Gyors lead time: Prototípus készítés 3 - 5 napon belül, nagy léptékű gyártás skálázható kapacitással.

• Tanúsított minőség: ISO 9001:2015 - kompatibilis teljes nyomon követhetőséggel.

Felfedezze portfóliójunkat a aoomtech.com vagy lépjen kapcsolatba mérnöki csapatunkkal az egyedi megoldásokért.

Hogyan találjunk megbízható partnert a nagy pontosságú bubor

Hogyan találjunk megbízható partnert a nagy pontosságú bubor

Útmutató a precíziós hardver CNC megmunkálás testreszabási s

Útmutató a precíziós hardver CNC megmunkálás testreszabási s

Mennyibe kerül a kis tételű CNC megmunkálás egyedi hardveral

Mennyibe kerül a kis tételű CNC megmunkálás egyedi hardveral

Gyakorlati útmutató a kis tételes CNC megmunkáláshoz: költsé

Gyakorlati útmutató a kis tételes CNC megmunkáláshoz: költsé