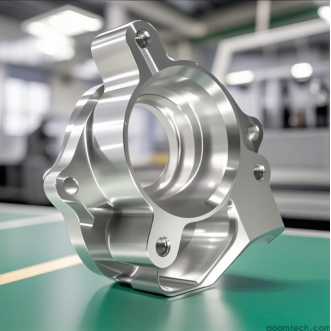

Processo di lavorazione del bullone CNC

Nella produzione di precisione, il processo di lavorazione dei bulloni CNC è un'operazione cruciale per le industrie che richiedono bulloni ad alta tolleranza. Come principale fornitore di servizi di lavorazione CNC, AOOM Technology fornisce soluzioni eccezionali di produzione di bulloni personalizzate per le applicazioni aerospaziali, automobilistiche e industriali.

Capire la lavorazione dei bulloni CNC

Il processo di lavorazione dei bulloni CNC prevede l'uso di torni o fresatrici controllati dal computer che trasformano barre di metallo grezzo in bulloni di precisione attraverso operazioni sequenziali tra cui la tornitura, la filettatura, la formazione della testa e la finitura superficiale. Le nostre macchine CNC a 5 assi raggiungono tolleranze di ±0,005mm, garantendo un perfetto ingranaggio delle filettature e una distribuzione uniforme della carica.

Vantaggi chiave della nostra produzione di bulloni CNC

1. Versatilità del materiale: Lavoriamo bulloni in acciaio inossidabile, titanio, alluminio e leghe esotiche

2. Precisione delle filettature: Profilo delle filettature ACME, UN, metrico e personalizzato con accuratezza certificata

3. Trattamenti superficiali: Rivestimento opzionale, anodizzazione o passivazione per la resistenza alla corrosione

4. Flessibilità della produzione a serie: Dalle quantità di prototipo a campagne di produzione di oltre 100.000 unità

Specifiche tecniche

Il nostro processo di lavorazione dei bulloni CNC può gestire:

• Gamma di diametri: M1,6 a M64

• Rapporti lunghezza - diametro fino a 12:1

• Tipi di teste: Esaagonale, a cricca, flangia e disegni personalizzati

• Conformità agli standard ISO 898, ASME B18.2 e DIN

Perché scelga la tecnologia di AOOM?

Con oltre 15 anni di esperienza nella lavorazione CNC, combinamo torni di tipo svizzero avanzati con rigorosi controlli di qualità (compresa la misurazione delle filettature al 100%) per fornire bulloni con proprietà meccaniche perfette. I nostri ingegneri ottimizzano ogni parametro di lavorazione, dalle velocità di taglio ai percorsi dell'utensile, garantendo la massima resistenza alla trazione e alla fatica.

Richiedi una valutazione gratuita del progetto su www.aoomtech.com per sperimentare la produzione di bulloni di precisione che elimina i problemi di assemblaggio e riduce i costi totali dei bulloni.

Quali sono i metodi di lavorazione CNC più convenienti per l

Quali sono i metodi di lavorazione CNC più convenienti per l

Cosa dovresti cercare in un produttore di parti hardware per

Cosa dovresti cercare in un produttore di parti hardware per

Parti hardware di precisione Produzione di massa CNC: la gui

Parti hardware di precisione Produzione di massa CNC: la gui

La tua guida alla lavorazione CNC di piccoli lotti ad alta p

La tua guida alla lavorazione CNC di piccoli lotti ad alta p