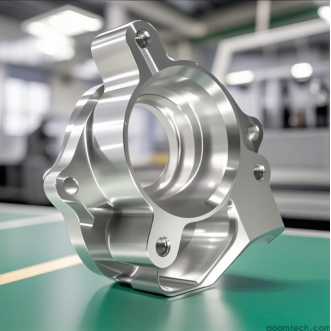

Parti del motore Processo di lavorazione CNC

Come professionista fornitore di servizi di lavorazione CNC di parti del motore, AOOM Technology si specializza nella fornitura di componenti ad alta precisione per applicazioni automotive, aerospaziali e industriali. Questo articolo esplora il processo tecnico, le misure di controllo di qualità e i nostri vantaggi competitivi in questo settore.

Perché scegliere la lavorazione CNC per i componenti del motore?

I componenti del motore richiedono estrema precisione e durata. La lavorazione CNC offre un'accuratezza a livello di micron (tipicamente ±0,005mm) e ripetibilità cruciali per testate di cilindro, pistoni, alberi a levasse e carceri di turbocompressori. I nostri centri CNC a 5 assi possono gestire geometrie complesse in materiali che vanno dalle leghe di alluminio alle superleghe di nichel ad alta temperatura.

Il nostro flusso di lavoro per la produzione di parti del motore

1. Selezione del materiale: Utilizziamo metalli di grado aerospaziale certificati (alluminio 6061 - T6, acciaio 434, Inconel 718)

2. Lavorazione di precisione: Lavorazione multi - asse simultanea con utensili attivi

3. Trattamento superficiale: Anodizzazione, trattamento termico o rivestimenti specializzati

4. Ispezione di qualità: Misurazione CMM e prove a pressione

Vantaggi tecnici di AOOM

I nostri servizi di lavorazione CNC per le parti del motore presentano:

• Più di 15 anni di esperienza nell'industria automobilistica

• Stabilimento di produzione certificato ISO 9001:2015

• Tornitrici Swiss - type avanzate per componenti a albero

• Sistema di tracciabilità del materiale al 100%

Per le parti del motore che richiedono tolleranze rigorose e prestazioni affidabili, contattare AOOM Technology all'indirizzo www.aoomtech.com per una consulenza tecnica e un preventivo.

Quali sono i metodi di lavorazione CNC più convenienti per l

Quali sono i metodi di lavorazione CNC più convenienti per l

Cosa dovresti cercare in un produttore di parti hardware per

Cosa dovresti cercare in un produttore di parti hardware per

Parti hardware di precisione Produzione di massa CNC: la gui

Parti hardware di precisione Produzione di massa CNC: la gui

La tua guida alla lavorazione CNC di piccoli lotti ad alta p

La tua guida alla lavorazione CNC di piccoli lotti ad alta p