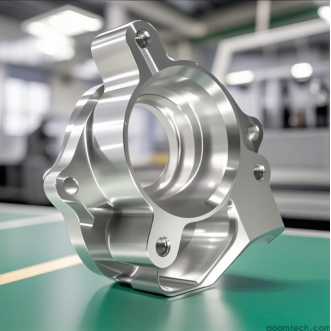

Lavorazioni personalizzate in acciaio inossidabile CNC: soluzioni di precisione per i tuoi progetti

Nell'esigente panorama industriale di oggi, la lavorazione personalizzata di acciaio inossidabile CNC è diventata una pietra miliare per i produttori che richiedono componenti duri e ad alta precisione. Come principale fornitore di servizi di lavorazione CNC, AOOM Technology si specializza nella fornitura di soluzioni personalizzate che soddisfano le tolleranze più severe e i requisiti di finitura superficiale.

Perché scegliere la lavorazione CNC per l'acciaio inossidabile?

L'eccezionale resistenza alla corrosione e le proprietà meccaniche dell'acciaio inossidabile lo rendono ideale per le applicazioni aerospaziali, mediche e automobilistiche. I nostri servizi di lavorazione personalizzata di acciaio inossidabile CNC sfruttano centri di fresatura e tornitura a 5 assi avanzati per produrre geometrie complesse con un'accuratezza a livello di micron. Il processo inizia con la selezione del materiale (gradi 304, 316 o 17 - 4PH) e prosegue attraverso la programmazione CAD/CAM fino all'ispezione finale di qualità.

Vantaggi chiave dei nostri servizi di lavorazione personalizzati

1. Ingegneria di precisione: Capacità di tolleranza di ±0,005mm per le dimensioni critiche

2. Opzioni di finitura superficiale: Dalle finiture specchio Ra .8μm alle superfici con texture

3. Dal prototipo alla produzione: Soluzioni scalabili con tempi di realizzazione rapidi

4. Esperienza nei materiali: Lavorazione di tutte le qualità di acciaio inossidabile senza indurre indurimento del lavoro

Applicazioni in tutti i settori

Le nostre capacità di lavorazione personalizzata di acciaio inossidabile CNC servono vari settori:

- Medico: Strumenti chirurgici e componenti di impianto

- Processo alimentare: Connettori igienici e parti di macchinari

- Energia: Corpi di valvole e componenti di pompe

- Automobile: Parti del sistema di carburante e carceri di turbocompressori

In AOOM Technology, combiniamo apparecchiature CNC di ingegneria tedesca con processi certificati ISO 9001 per fornire parti in acciaio inossidabile che superano gli standard del settore. Il nostro team di ingegneri lavora a stretto contatto con i clienti per ottimizzare i progetti per la produttività e l'efficienza dei costi senza compromettere la qualità.

Quali sono i metodi di lavorazione CNC più convenienti per l

Quali sono i metodi di lavorazione CNC più convenienti per l

Cosa dovresti cercare in un produttore di parti hardware per

Cosa dovresti cercare in un produttore di parti hardware per

Parti hardware di precisione Produzione di massa CNC: la gui

Parti hardware di precisione Produzione di massa CNC: la gui

La tua guida alla lavorazione CNC di piccoli lotti ad alta p

La tua guida alla lavorazione CNC di piccoli lotti ad alta p