Metodo di calcolo dei costi di lavorazione CNC

Come professionista fornitore di servizi di lavorazione CNC, AOOM Technology comprende che il calcolo dei costi è una preoccupazione cruciale per i responsabili dell'acquisto e gli ingegneri. Questa guida spiegherà i fattori chiave che influenzano i costi di lavorazione CNC e come ottimizzamo i prezzi su AOOM.

Fattori chiave nel calcolo dei costi di lavorazione CNC

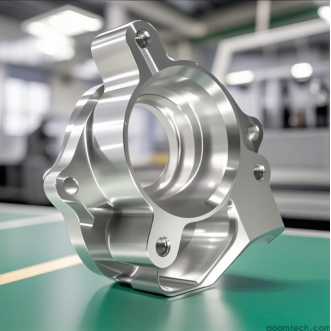

1. Costi del materiale: Differenti metalli (alluminio, acciaio, titanio) e plastiche hanno prezzi di materia prima variabili che influenzano direttamente il costo totale.

2. Tempo di macchina: Geometrie complesse che richiedono un tempo di lavorazione più lungo aumentano i costi. Le nostre avanzate macchine a 5 assi in AOOM riducono i tempi di ciclo.

3. Costi del lavoro: Tempo dei tecnici specializzati per la programmazione, l'allestimento e l'ispezione della qualità.

4. Finestra superficiale: Processi aggiuntivi come l'anodizzazione o la lucidatura aumentano il costo base di lavorazione CNC.

L'approccio di ottimizzazione dei costi di AOOM

• Progettazione per la produttività: I nostri ingegneri esaminano i vostri disegni per suggerire modifiche per il risparmio di costi senza compromettere la funzionalità.

• Sconti per quantità: Quantità maggiori di solito riducono i costi per unità attraverso una migliore utilizzazione del materiale e l'amortamento dell'allestimento.

• Utensili avanzati: La nostra moderna attrezzatura CNC raggiunge tolleranze più strette con meno spreco di materiale.

Struttura dei prezzi trasparente

In AOOM, forniamo preventivi dettagliati suddividendo i costi del materiale, i tempi di macchina, i processi di finitura e qualsiasi requisito speciale. Questa trasparenza aiuta i nostri clienti a prendere decisioni informate sui loro progetti di lavorazione CNC.

Contattate AOOM Technology oggi stesso per una valutazione gratuita del progetto e un preventivo su misura per le vostre esigenze specifiche.

Quali sono i metodi di lavorazione CNC più convenienti per l

Quali sono i metodi di lavorazione CNC più convenienti per l

Cosa dovresti cercare in un produttore di parti hardware per

Cosa dovresti cercare in un produttore di parti hardware per

Parti hardware di precisione Produzione di massa CNC: la gui

Parti hardware di precisione Produzione di massa CNC: la gui

La tua guida alla lavorazione CNC di piccoli lotti ad alta p

La tua guida alla lavorazione CNC di piccoli lotti ad alta p