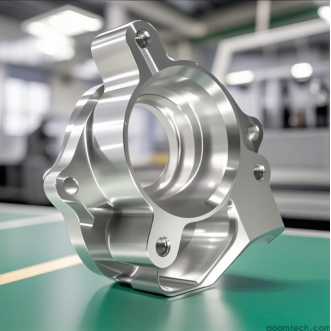

Processo di lavorazione CNC in rame: tecniche e applicazioni di precisione

Come leader fornitore di servizi di lavorazione CNC, AOOM Technologies si specializza nella fornitura di componenti in rame di alta precisione per settori che vanno dall'elettronica all'aerospazio. Questo articolo esplora il processo di lavorazione CNC del rame, i suoi vantaggi e come la nostra esperienza garantisce risultati superiori.

Capire la lavorazione CNC del rame

La lavorazione CNC del rame comporta tecniche di produzione sottrattive per modellare materiali in rame grezzo in componenti precisi. A causa dell'eccellente conduttività e delle proprietà termiche del rame, richiede strategie di lavorazione specializzate per mantenere l'accuratezza dimensionale mentre si previene la deformazione del materiale.

Passi chiave nella lavorazione CNC del rame

1. Selezione del materiale: Scegliere la giusta lega di rame (C10100, C11000, ecc.) sulla base delle esigenze di conduttività e meccaniche.

2. Ottimizzazione del percorso dell'utensile: I nostri ingegneri programmano i percorsi dell'utensile tenendo conto della consistenza appiccicosa del rame, riducendo l'usura degli utensili.

3. Gestione del refrigerante: Implementare la lavorazione a temperatura controllata per prevenire l'indurimento del lavoro.

4. Finestra superficiale: Processi opzionali come l'elettropolimento per una maggiore conduttività e resistenza alla corrosione.

Vantaggi tecnici di AOOM

Con oltre 15 anni di esperienza, AOOM Technologies offre:

- Centri di lavorazione dedicati al rame con mandrini ad alta velocità (fino a 30.000 RPM)

- Laboratorio di metrologia interno per il controllo di qualità a livello di micron

- Capacità dalla prototipazione alla produzione di massa

Visita il nostro sito web per esplorare i casi di studio delle nostre soluzioni di lavorazione CNC del rame.

Applicazioni in tutti i settori

I nostri componenti in rame di precisione svolgono funzioni critiche in:

• Barre collettrici e connettori elettrici

• Scambiatori di calore e sistemi di raffreddamento

• Componenti di schermatura RF

• Sistemi elettrici automobilistici e aerospaziali

Per risultati ottimali nel vostro prossimo progetto CNC in rame, contatta la squadra di ingegneria di AOOM per un'analisi DFM e una consulenza tecnica.

Quali sono i metodi di lavorazione CNC più convenienti per l

Quali sono i metodi di lavorazione CNC più convenienti per l

Cosa dovresti cercare in un produttore di parti hardware per

Cosa dovresti cercare in un produttore di parti hardware per

Parti hardware di precisione Produzione di massa CNC: la gui

Parti hardware di precisione Produzione di massa CNC: la gui

La tua guida alla lavorazione CNC di piccoli lotti ad alta p

La tua guida alla lavorazione CNC di piccoli lotti ad alta p