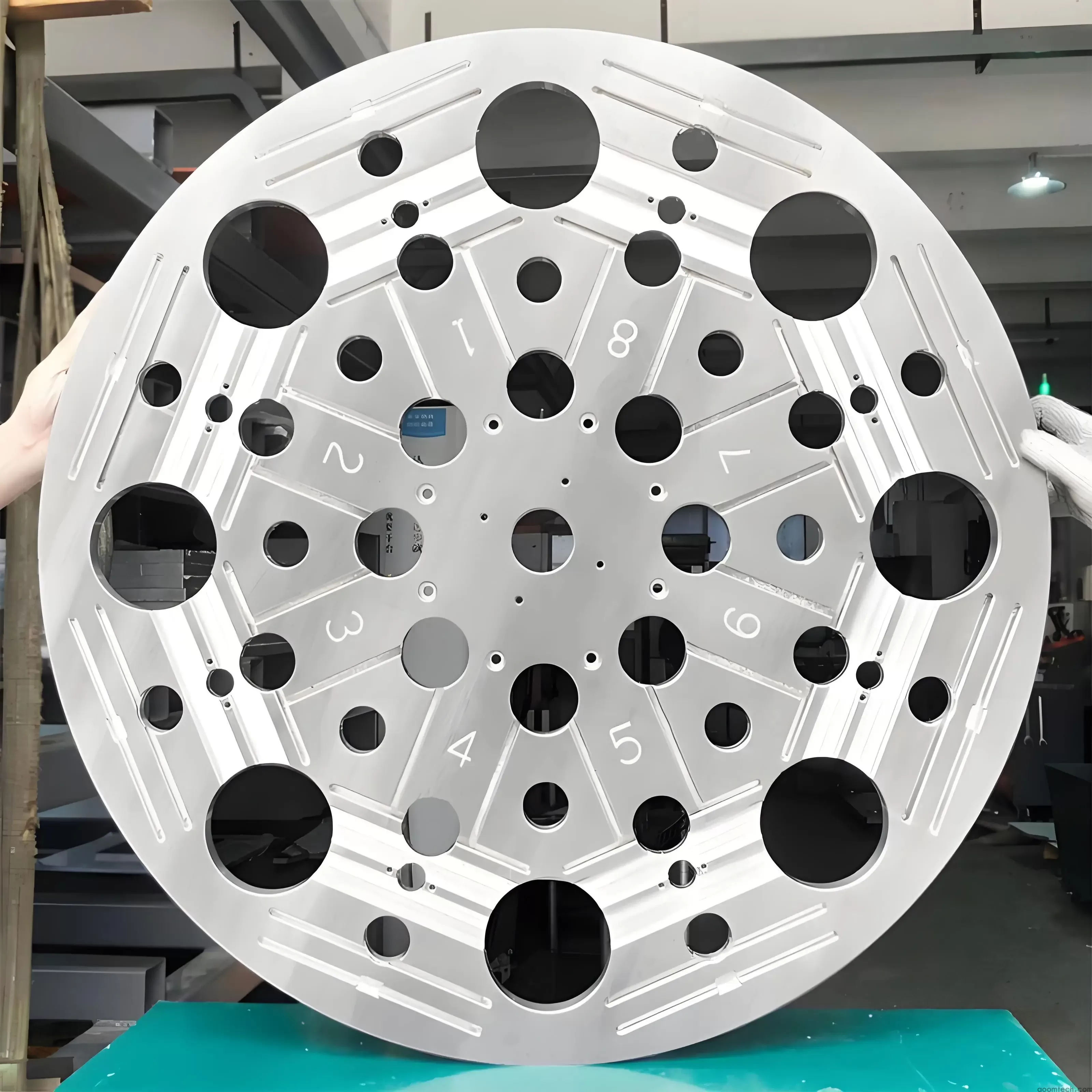

Lavorazione di grandi pezzi CNC

Come leader fornitore di servizi di lavorazione CNC, AOOM Technology si specializza nella produzione di precisione di componenti su larga scala per settori che vanno dall'aerospazio all'energia. Questo articolo esplora le sfide tecniche e le soluzioni nella lavorazione di grandi pezzi CNC.

Capire la lavorazione di grandi pezzi CNC

La lavorazione di pezzi di grandi dimensioni CNC si riferisce alla produzione di componenti in genere superiori a 1 metro in qualsiasi dimensione, che richiedono attrezzature e competenze specializzate. In AOOM, utilizziamo fresatrici a portale e centri di lavoro orizzontali con buste di lavoro fino a 5m × 3m × 2m per gestire tali progetti.

Sfide chiave nella lavorazione di grandi pezzi

1. Stabilità del materiale : I grandi pezzi metallici sono soggetti a deformazioni termiche durante la lavorazione

2. Ottimizzazione del percorso dell'utensile : Richiede una programmazione CAM avanzata per mantenere la precisione

3. Controllo delle vibrazioni : Le nostre macchine dispongono di sistemi di smorzamento attivi per una migliore finitura superficiale

Vantaggi tecnici di AOOM

La nostra struttura dispone di:

- Capacità di lavorazione a 5 assi simultanei per geometrie complesse

- Ispezione sulla macchina con tracciatori laser

- Laboratorio a temperatura controllata (±1°C) per la stabilità termica

- Rigoroso processo di controllo qualità che include la verifica CMM

Applicazioni industriali

Produciamo regolarmente:

- Componenti strutturali aerospaziali

- Case per turbini del settore energetico

- Basi e telai di macchine industriali

- Assemblaggi su larga scala di attrezzature per il trasporto

Perché scegliere AOOM per i vostri bisogni di grandi pezzi

Con oltre 15 anni di esperienza nella lavorazione CNC, offriamo:

1. Soluzione turnkey dal disegno al prodotto finito

2. Tolleranze strette (±0,05mm raggiungibili)

3. Esperienza con i materiali, inclusi alluminio, acciaio e leghe di titanio

4. Gestione della qualità certificata ISO 9001

Contatta la nostra squadra di ingegneri su AOOM Technology per discutere i requisiti del vostro progetto di lavorazione su larga scala e ricevere una proposta di soluzione personalizzata.

Padroneggiare la lavorazione CNC composita: risolvere sfide

Padroneggiare la lavorazione CNC composita: risolvere sfide

La tua guida ai servizi di lavorazione CNC personalizzati: d

La tua guida ai servizi di lavorazione CNC personalizzati: d

La tua guida definitiva ai servizi di lavorazione CNC in acc

La tua guida definitiva ai servizi di lavorazione CNC in acc

Come scegliere una fabbrica di lavorazione CNC di fascia alt

Come scegliere una fabbrica di lavorazione CNC di fascia alt