Che precisione può raggiungere la lavorazione CNC a 3 assi?

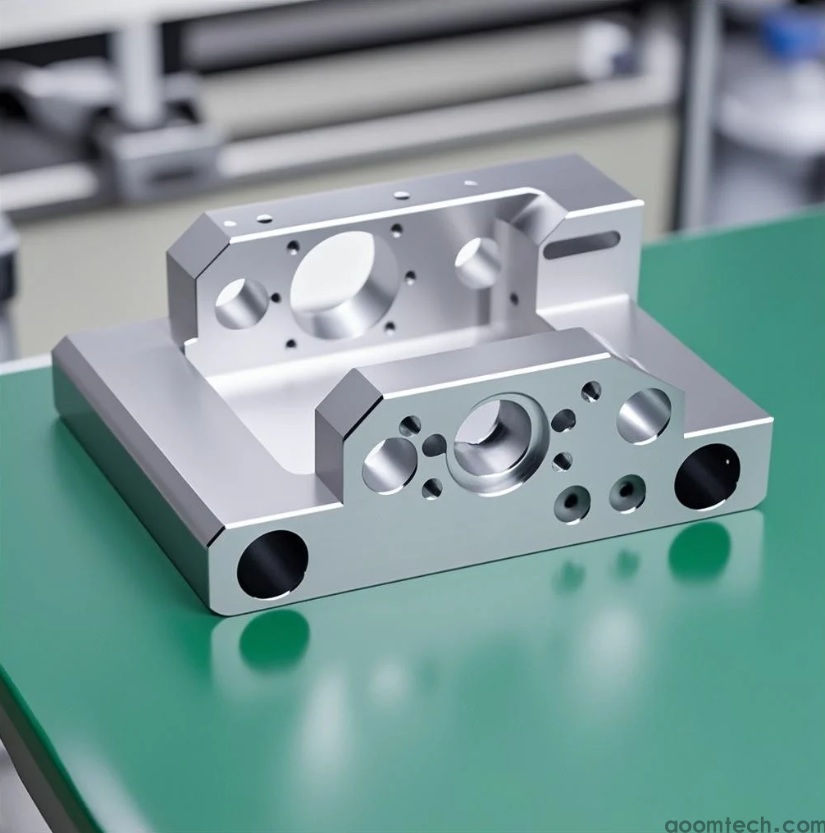

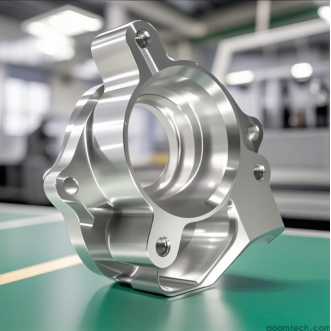

Come professionista fornitore di servizi di lavorazione CNC, AOOM Technology comprende che la precisione è la pietra miliare dell'eccellenza produttiva. Quando i clienti chiedono informazioni sulle capacità di lavorazione CNC a 3 assi, di solito cercano chiarezza sulle tolleranze raggiungibili e sulle finiture superficiali per i loro progetti.

Comprendere la precisione della lavorazione CNC a 3 assi

Le macchine CNC standard a 3 assi possono in genere mantenere tolleranze di ±0,005" (±0,127mm) per la maggior parte dei materiali, con alcune macchine ad alte prestazioni che raggiungono ±0,001" (±0,025mm) in condizioni ottimali. La precisione effettiva dipende da molti fattori, tra cui la calibrazione della macchina, la qualità dell'utensile, le caratteristiche del materiale e l'esperienza dell'operatore.

Fattori chiave che influenzano la precisione di lavorazione

1. Rigidità della macchina: La nostra attrezzatura CNC tedesca e giapponese mantiene un'eccezionale stabilità

2. Selezione dell'utensile: Utilizziamo freshetta in carburo premium di marche leader

3. Controllo della temperatura: L'atelier a controllo climatico previene l'espansione termica

4. Sistemi di misurazione: Le macchine CMM Mitutoyo verificano le dimensioni delle parti

Capacità di precisione di AOOM

Attraverso i nostri processi certificati ISO 9001, forniamo costantemente:

- Tolleranza standard: ±0,005" (±0,127mm)

- Tolleranza ad alta precisione: ±0,001" (±0,025mm)

- Finiture superficiali fino a Ra 0,8μm (32μin)

La nostra squadra di ingegneri può suggerire le strategie di lavorazione ottimali per bilanciare i requisiti di precisione con l'efficienza dei costi.

Applicazioni della lavorazione di precisione a 3 assi

Questa tecnologia serve i settori che richiedono tolleranze strette:

• Componenti aerospaziali

• Prototipi di dispositivi medici

• Parti automobilistiche

• Sistemi di automazione industriale

In AOOM Technology, combiniamo attrezzature avanzate con decenni di esperienza nella lavorazione per fornire componenti di precisione che soddisfano le vostre specifiche esatte. Contatta la nostra squadra di ingegneri per discutere i requisiti specifici del tuo progetto.

Quali sono i metodi di lavorazione CNC più convenienti per l

Quali sono i metodi di lavorazione CNC più convenienti per l

Cosa dovresti cercare in un produttore di parti hardware per

Cosa dovresti cercare in un produttore di parti hardware per

Parti hardware di precisione Produzione di massa CNC: la gui

Parti hardware di precisione Produzione di massa CNC: la gui

La tua guida alla lavorazione CNC di piccoli lotti ad alta p

La tua guida alla lavorazione CNC di piccoli lotti ad alta p