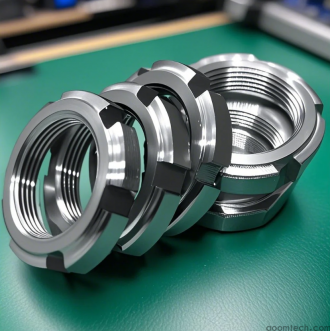

CNC 정밀 제품 가공 프로세스

선두로 # CNC Precision Product Machining Process specialist, AOOM Technologies delivers unmatched precision manufacturing solutions for industries requiring micron-level accuracy. Our ISO-certified facility combines advanced machinery with decades of technical expertise to transform raw materials into high-performance components.

정밀 CNC 가공의 과학

진정한 정밀 가공은 재료의 행동을 이해하는 것에서 시작됩니다. 우리 엔지니어들은 금속 합금, 엔지니어링 플라스틱 및 복합 재료를 분자 수준에서 분석하여 최적을 결정합니다. # CNC Precision Product Machining Process parameters. This scientific approach ensures dimensional stability even for parts with tolerances as tight as ±.005mm.

정밀 프로세스의 주요 이점

1. Multi-Axis Synchronization: 5-axis simultaneous machining eliminates secondary operations

2. Thermal Compensation: Real-time temperature monitoring prevents thermal deformation

3. Surface Integrity Control: Proprietary toolpath strategies achieve Ra .2μm finishes

4. Digital Twin Verification: All programs undergo virtual machining before production

산업별 애플리케이션

우리 # CNC Precision Product Machining Process serves critical sectors including:

- Aerospace: Turbine blades with cooling channels

- Medical: FDA-compliant surgical instruments

- Automotive: Fuel injection components

- Electronics: EMI-shielding enclosures

AOOM의 정밀 가공을 선택하는 이유는 무엇입니까?

표준 CNC 상점과 달리 우리는 군사급 품질 프로토콜을 구현합니다.

• In-process CMM inspection every 5 parts

• Material traceability documentation

• On-site metallurgical lab for material verification

• Dedicated engineering support throughout product lifecycle

당사의 정밀 가공 솔루션이 제품 성능을 높이는 방법을 알아보십시오. Contact AOOM Technologies for a free design-for-manufacturability analysis today.

CNC 스테인리스 스틸 가공 견적: 가격에 영향을 미치는 요인

CNC 스테인리스 스틸 가공 견적: 가격에 영향을 미치는 요인

CNC 제품 제조 및 가공 제조업체

CNC 제품 제조 및 가공 제조업체

CNC 가공 스테인리스 의료 부품

CNC 가공 스테인리스 의료 부품

CNC 비표준 맞춤 가공 제조업체

CNC 비표준 맞춤 가공 제조업체