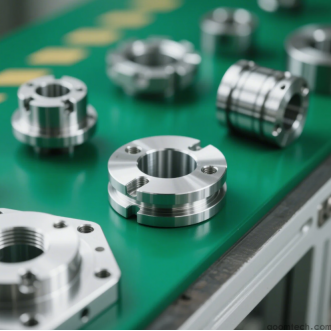

알루미늄 부품의 CNC 배치 가공 프로세스

선두로 CNC machining service provider, AOOM Technologies specializes in high-volume aluminum component manufacturing with precision and efficiency. This article will explore the critical aspects of CNC batch machining for aluminum parts, addressing the key concerns of procurement managers and engineers.

알루미늄을 위한 CNC 배치 가공 이해

배치 가공은 CNC 기술을 사용하여 미리 정해진 수량으로 동일한 알루미늄 부품을 생산하는 것을 말합니다. AOOM에서는 100 ~ 700 시리즈의 알루미늄 합금을 처리할 수 있는 고급 3/4/5 축 CNC 기계를 사용하여 .01mm 이내의 치수 정확도를 보장합니다.

주요 프로세스 단계

1. Material Preparation: Selection of appropriate aluminum grade based on mechanical requirements

2. Fixture Design: Custom workholding solutions for batch consistency

3. Toolpath Optimization: CAM programming for maximum material removal rates

4. Quality Control: In-process inspection with CMM and surface roughness testers

배치 가공 서비스의 장점

• Cost-effective production for quantities from 50-10,000+ units

• 15-30% faster cycle times through optimized tooling strategies

• Dedicated production cells for aluminum-specific machining

• ISO 9001-certified quality management system

산업 응용 프로그램

당사의 배치 가공 기능은 다음과 같습니다.

- Aerospace: Structural components and housings

- Automotive: Engine parts and transmission elements

- Electronics: Heat sinks and enclosures

- Medical: Instrumentation components

12년 이상의 알루미늄 가공 경험을 바탕으로 AOOM 테크놀로지스는 신뢰할 수 있는 제품을 제공합니다. CNC batch machining solutions that balance precision, speed, and cost-efficiency. Contact our engineering team today to discuss your specific project requirements.

CNC 부품 가공 제조업체

CNC 부품 가공 제조업체

CNC 기계가 할 수 있는 제품

CNC 기계가 할 수 있는 제품

CNC 베릴륨 구리 가공 공정

CNC 베릴륨 구리 가공 공정

CNC 하드웨어 가공 공급업체

CNC 하드웨어 가공 공급업체