CNC 가공으로 단단한 재료를 처리하는 방법

CNC 하드 재료 가공 이해

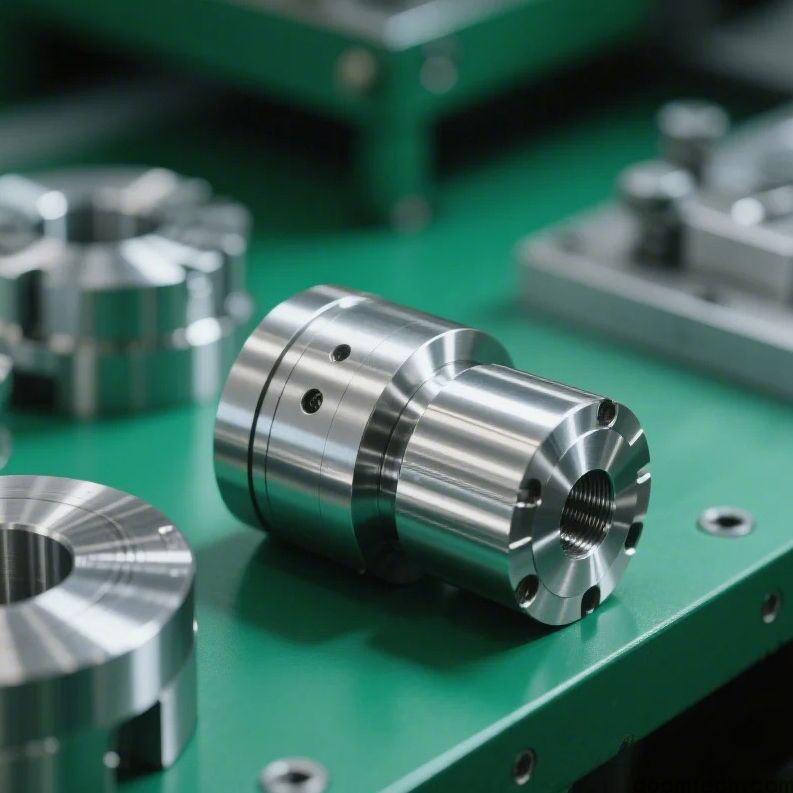

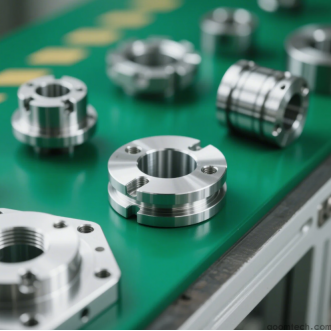

티타늄, 경화강 또는 Inconel과 같은 단단한 재료를 가공하려면 전문화가 필요합니다. CNC machining techniques. At AOOM, we employ advanced tooling strategies and rigid machine setups to maintain precision while minimizing tool wear. The key challenges include heat generation, excessive tool pressure, and achieving desired surface finishes.

경질 CNC 가공의 중요 기법

1. Tool selection: We use carbide or CBN tools with specialized coatings (TiAlN, diamond-like carbon) that withstand high temperatures.

2. Optimized cutting parameters: Reduced feed rates with higher spindle speeds prevent work hardening.

3. Rigid fixturing: Our 5-axis machines feature vibration-dampening systems for stability during heavy cuts.

4. Coolant management: Through-tool coolant delivery prevents thermal deformation of workpieces.

AOOM의 단단한 재료 가공 능력

시설 기능:

• 40+ CNC mills/lathes with 15+ dedicated to hard material processing

• In-house tool grinding for custom geometries

• CMM inspection to ensure ±.005mm tolerances

• Post-processing options including heat treatment and precision grinding

산업 응용 프로그램

우리는 경질 가공이 제품 성능과 수명에 중요한 항공 우주(터빈 부품), 의료(수술 임플란트), 자동차(성능 드라이브트레인) 산업을 제공합니다.

CNC 부품 가공 제조업체

CNC 부품 가공 제조업체

CNC 기계가 할 수 있는 제품

CNC 기계가 할 수 있는 제품

CNC 베릴륨 구리 가공 공정

CNC 베릴륨 구리 가공 공정

CNC 하드웨어 가공 공급업체

CNC 하드웨어 가공 공급업체