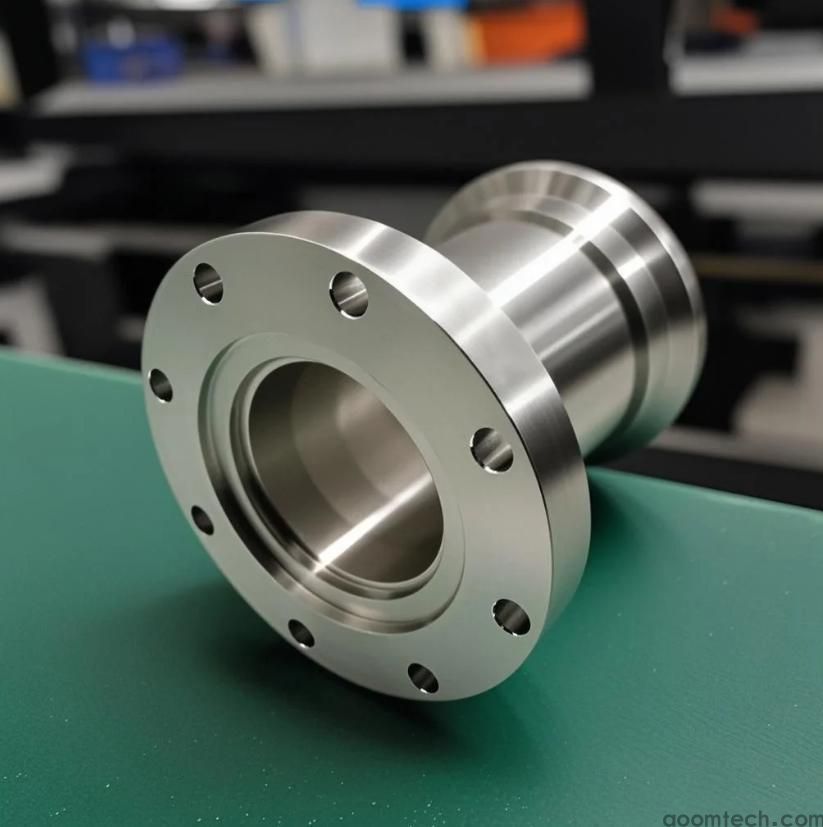

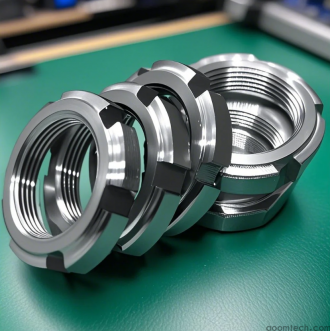

정밀 제조를 위한 CNC 턴 커스터마이징 서비스

현대 제조에서 CNC turning customization has become a cornerstone for industries requiring high-precision components. As a trusted provider at AOOM Technologies, we specialize in delivering tailored solutions that meet stringent quality standards while optimizing production efficiency.

CNC 턴 커스터마이징이란?

CNC 턴 커스터마이징 절삭 공구가 재료를 제거하는 동안 공작물을 회전시켜 정밀한 부품을 만드는 과정을 말합니다. 이 방법은 엄격한 공차(.005mm)를 가진 원통형 또는 원뿔형 모양을 생성하는 데 이상적입니다. AOOM의 고급 CNC 선반은 다축 작동을 지원하여 알루미늄 합금에서 티타늄에 이르는 재료의 나사산, 홈 및 테이퍼 기능과 같은 복잡한 기하학적 구조를 가능하게 합니다.

맞춤형 CNC 전환을 위한 AOOM 선택의 주요 이점

1. Material Expertise: We machine over 50+ metals/plastics, including challenging materials like Inconel and PEEK.

2. Precision Guarantee: ISO 9001-certified processes ensure dimensional accuracy up to IT6 grade.

3. Rapid Prototyping: 3-5 day lead times for prototype batches through our dedicated quick-turn service.

4. Surface Finish Options: From Ra .8μm mirror finishes to powder coating/anodizing.

맞춤형 전환 솔루션을 제공하는 산업

• Aerospace: Flight-critical components like hydraulic fittings

• Medical: FDA-compliant surgical instrument parts

• Automotive: High-volume fuel injection components

• Energy: Corrosion-resistant valve bodies for offshore applications

NAT의 엔드 투 엔드 사용자 지정 워크플로우

1. Design Consultation: DFM analysis using SolidWorks/Creo software

2. Material Selection: Technical guidance on optimal grade selection

3. Process Planning: Toolpath optimization for minimal material waste

4. Quality Validation: CMM inspection with comprehensive reports

AOOM 테크놀로지스에서는 독일 엔지니어링 DMG MORI 기계와 15년 이상의 가공 전문 지식을 결합하여 제공합니다. CNC turning customization that exceeds expectations. Request your free project evaluation today to experience precision manufacturing redefined.

CNC 스테인리스 스틸 가공 견적: 가격에 영향을 미치는 요인

CNC 스테인리스 스틸 가공 견적: 가격에 영향을 미치는 요인

CNC 제품 제조 및 가공 제조업체

CNC 제품 제조 및 가공 제조업체

CNC 가공 스테인리스 의료 부품

CNC 가공 스테인리스 의료 부품

CNC 비표준 맞춤 가공 제조업체

CNC 비표준 맞춤 가공 제조업체