Proses Pemesinan Acuan CNC

Memahami Pemesinan Acuan CNC

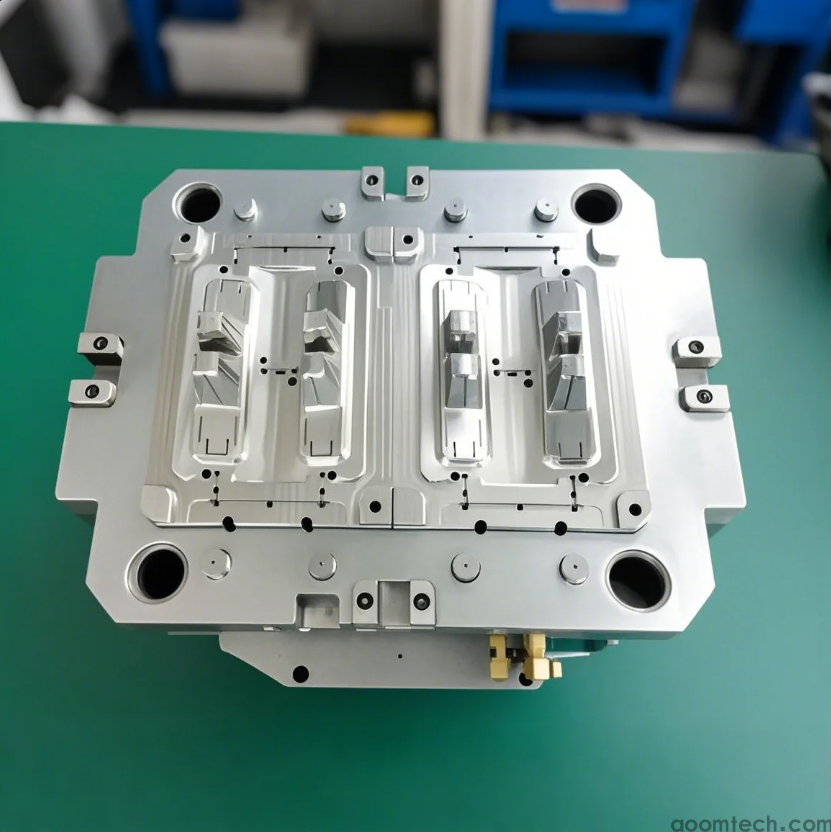

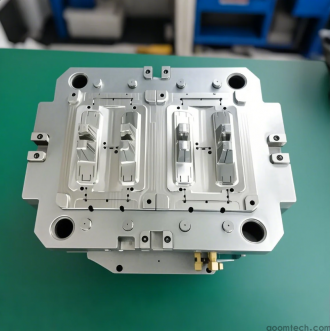

Yang CNC mold machining process is a critical manufacturing technique that transforms raw materials into precision molds used across various industries. At AOOM, we specialize in delivering high-quality CNC machined molds with exceptional accuracy and surface finish.

Pecahan Proses Langkah demi Langkah

1. Design and Programming: Our engineers create 3D CAD models and generate precise CNC toolpaths using advanced CAM software.

2. Material Selection: We carefully choose appropriate materials (typically tool steels or aluminum alloys) based on mold requirements.

3. Rough Machining: The initial shaping removes bulk material efficiently using high-power cutting tools.

4. Semi-Finishing: Intermediate operations bring the mold closer to final dimensions while maintaining proper tolerances.

5. Precision Finishing: The CNC machining process achieves final dimensions and surface quality through meticulous finishing passes.

6. Quality Inspection: We verify all critical dimensions using CMMs and other precision measuring instruments.

Kelebihan Teknikal AOOM

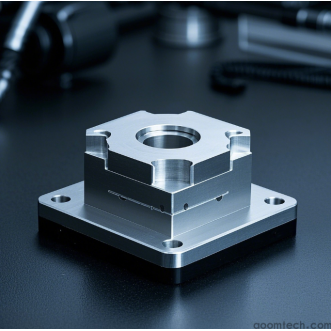

Kemudahan kami menampilkan mesin CNC 5 paksi terkini yang mampu menghasilkan geometri kompleks dengan ketepatan ± .01mm. Kami melaksanakan kawalan proses yang ketat sepanjang CNC mold machining workflow to ensure consistent quality.

Aplikasi Merentasi Industri

CNC acuan dimesin dari AOOM berkhidmat pelbagai sektor termasuk automotif, aeroangkasa, peranti perubatan, dan elektronik pengguna. Kepakaran kami meliputi acuan suntikan, mati pemutus acuan, dan setem mati.

Mengapa Memilih AOOM untuk Pembuatan Acuan Anda

Dengan pengalaman yang luas dalam pengeluaran acuan CNC, AOOM menawarkan masa memimpin yang kompetitif, penyelesaian kos efektif, dan sokongan teknikal sepanjang kitaran hayat projek anda. Lawati laman web kami di https://www.aoomtech.com / untuk meneroka keupayaan kami dan meminta sebut harga.

Pembekal Pemesinan Ketepatan CNC

Pembekal Pemesinan Ketepatan CNC

Yang merupakan pembekal perkhidmatan pemesinan ketepatan CNC

Yang merupakan pembekal perkhidmatan pemesinan ketepatan CNC

Proses Pemesinan Acuan CNC

Proses Pemesinan Acuan CNC

Pemesinan Tersuai Produk CNC: Penyelesaian Ketepatan untuk K

Pemesinan Tersuai Produk CNC: Penyelesaian Ketepatan untuk K