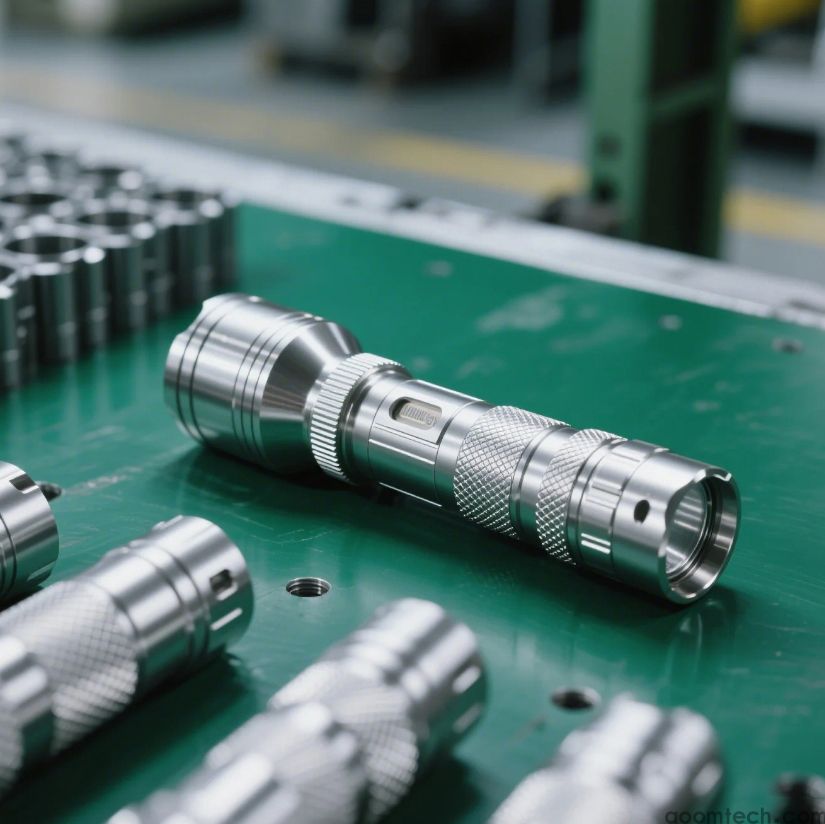

Apakah Toleransi yang Boleh Anda Capai dengan Pemesinan Bar CNC? Panduan Praktikal

Hai, rakan jurutera dan pakar perolehan! 👋 Pernah mendapati diri anda merenung lukisan teknikal, tertanya-tanya jika pembekal pemesinan bar CNC anda boleh actually hit those tiny tolerance numbers? You're not alone. I've been in those meetings where everyone nods, but deep down, there's that nagging question: "What's realistically achievable?" Let's cut through the marketing fluff and talk real numbers. 🤔

Jadi, Apakah Tawaran Sebenar dengan Ketepatan Pemesinan Bar CNC?

Perkara pertama dahulu, mari kita jawab soalan besar. Untuk kebanyakan kerja pemesinan bar CNC standard, anda secara amnya boleh mengharapkan untuk memegang toleransi di sekeliling ±.025 mm to ±.05 mm (±.001" to ±.002"). That's about the thickness of a human hair! But—and this is a big but—this isn't a guarantee for every single part. It depends on a whole bunch of factors that we'll dig into next. I've seen shops consistently hit these numbers on aluminum and brass, but when it comes to some tricky plastics or super-alloys, the story can change.

Apakah Faktor Yang Sebenarnya Kacau Dengan Ketepatan Pemesinan Anda?

Ia bukan hanya mengenai mesin. Berikut ialah suspek biasa yang boleh membuat atau memecahkan matlamat toleransi anda:

✅ The Material Itself: Some materials are just easier to work with. Aluminum is pretty forgiving and stable, making it a dream for tight tolerances. But something like stainless steel? It can be a bit of a diva, moving around with heat and stress. The exact way different alloys behave under the cutting tool is something I'm still wrapping my head around.

✅ Machine Condition and Age: A brand-new, high-end Swiss-type lathe is a precision beast. An older, worn-out machine might struggle. It's that simple.

✅ The Length of the Part: This is a big one that often gets overlooked. Trying to hold a tight tolerance on a long, skinny bar? That's much harder than on a short, stubby part. Vibration and deflection become your enemies.

Bagaimanakah Anda Boleh Membantu Pembekal Anda Mencecah Toleransi Yang Lebih Ketat Itu?

Percaya atau tidak, anda juga mempunyai peranan untuk dimainkan! Begini cara anda boleh menyediakan projek anda untuk berjaya:

🔧 Be Smart with Your Tolerances: Don't just call out super tight tolerances everywhere on the drawing. I always ask my team, "Does this surface really need to be that precise?" Only apply tight tolerances to critical features. This saves cost and headache.

🔧 Talk to Your Machinist Early: Get their input during the design phase. They might suggest a small change that makes the part much easier and cheaper to machine accurately.

🔧 Choose the Right Material: If high precision is your goal, maybe an aluminum grade is a better bet than that specific stainless steel you had in mind. Discuss the options.

Adakah "Lebih Ketepatan" Sentiasa Jawapan yang Betul?

Inilah dua sen saya, daripada melihat beratus-ratus projek. Mengejar toleransi paling ketat mutlak yang mungkin selalunya menjadi perangkap. 🤯 Kos tidak meningkat secara linear; ia naik seperti kayu hoki. Ketepatan .01 mm terakhir itu mungkin menggandakan kos bahagian anda. Anda perlu bertanya: What does the function of the part actually require? Sometimes, "good enough" is not just good enough—it's the smartest business decision. Perfection can be the enemy of profitability.

Yang dikatakan, untuk komponen kritikal dalam aeroangkasa atau peranti perubatan, ketepatan yang melampau itu tidak boleh dirunding. Tetapi untuk banyak aplikasi umum, mungkin ia berlebihan. Kemahiran sebenar adalah mengetahui perbezaannya.

Daripada pengalaman saya, hasil terbaik datang daripada perkongsian. Ia bukan hanya tentang mendorong pembekal untuk harga terendah dan ketepatan tertinggi. Ia mengenai komunikasi yang jelas, jangkaan realistik dan memahami pertukaran. Saya mendapati bahawa pendahuluan tentang keperluan belanjawan dan prestasi anda membawa kepada proses yang lebih lancar dan produk akhir yang lebih baik. 🚀 Hanya sesuatu yang perlu difikirkan untuk projek anda yang seterusnya.

Panduan Anda untuk Pemesinan CNC Kelompok Kecil Ketepatan Ti

Panduan Anda untuk Pemesinan CNC Kelompok Kecil Ketepatan Ti

Bahagian Ketepatan Tinggi Kecil Pemesinan CNC: Pertimbangan

Bahagian Ketepatan Tinggi Kecil Pemesinan CNC: Pertimbangan

Apakah Faktor Yang Benar-benar Mempengaruhi Kos Pemesinan CN

Apakah Faktor Yang Benar-benar Mempengaruhi Kos Pemesinan CN

Untuk Apa Produk Pemesinan Ketepatan CNC Boleh Digunakan? Pa

Untuk Apa Produk Pemesinan Ketepatan CNC Boleh Digunakan? Pa