CNC Precisie Product bewerkingsproces

Als leidend # CNC Precision Product Machining Process specialist levert AOOM Technologies onmatchebare precisieproductieoplossingen voor industrieën die micron - niveau nauwkeurigheid vereisen. Onze door ISO gecertificeerde faciliteit combineert geavanceerde machines met tientallen jaren technische expertise om grondstoffen om te zetten in hoogprestatiecomponenten.

De wetenschap achter precisie CNC - bewerking

Echte precisiebewerking begint met het begrijpen van materiaalgedrag. Onze ingenieurs analyseren metaallegeringen, technische kunststoffen en composietmaterialen op moleculair niveau om optimale # CNC Precision Product Machining Process parameters te bepalen. Deze wetenschappelijke benadering zorgt voor dimensionele stabiliteit zelfs voor onderdelen met toleranties zo strak als ±.005mm.

Belangrijkste voordelen van ons precisieproces

1. Multi - Assisynchronisatie: 5 - assige gelijktijdige bewerking elimineert secundaire operaties

2. Thermische compensatie: Real - time temperatuurmonitoring voorkomt thermische vervorming

3. Oppervlakteintegriteitscontrole: Eigen gereedschapspadstrategieën bereiken Ra .2μm finishes

4. Digital Twin-verificatie: Alle programma's ondergaan virtuele bewerking voordat ze in productie gaan

Industrie - specifieke toepassingen

Onze # CNC Precision Product Machining Process bedient kritieke sectoren, waaronder:

- Lucht - en ruimtevaart: Turbinebladen met koelkanalen

- Medisch: FDA - conforme chirurgische instrumenten

- Automobiel: Brandstofinjectiecomponenten

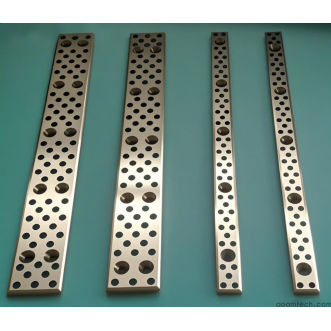

- Elektronica: EMI - schermende behuizingen

Waarom kiezen voor AOOM 's precisiebewerking?

In tegenstelling tot standaard CNC - winkels implementeren we kwaliteitsprotocollen van militaire kwaliteit:

• In - proces CMM - inspectie bij elke 5 onderdelen

• Materiële traceerbaarheidsdocumentatie

• Op - locatie metallurgisch laboratorium voor materiaalverificatie

• Toegewezen technische ondersteuning gedurende de gehele productlevenscyclus

Ontdek hoe onze precisiebewerkingsoplossingen uw productprestaties kunnen verbeteren. Contact AOOM Technologies voor een gratis design - for - manufacturability analyse vandaag.

Vijf kerntechnologieën voor CNC-bewerking Precisiecontrole v

Vijf kerntechnologieën voor CNC-bewerking Precisiecontrole v

5 Key Control-technieken om vervorming op te lossen bij CNC-

5 Key Control-technieken om vervorming op te lossen bij CNC-

CNC-bewerking van drijfstangen: hoe te zorgen voor boorpreci

CNC-bewerking van drijfstangen: hoe te zorgen voor boorpreci

Chrome Alloy CNC-bewerking _ Wat zijn de bewerkingsmoeilijkh

Chrome Alloy CNC-bewerking _ Wat zijn de bewerkingsmoeilijkh