CNC-batchbewerkingsproces voor aluminium onderdelen

Als leidend CNC - bewerkingsserviceaanbieder specialiseert AOOM Technologies zich in de hoogvolume productie van aluminiumcomponenten met precisie en efficiëntie. Dit artikel gaat in op de cruciale aspecten van CNC - batchbewerking voor aluminiumonderdelen en beantwoordt de belangrijkste vragen van inkoopmanagers en ingenieurs.

CNC - batchbewerking voor aluminium begrijpen

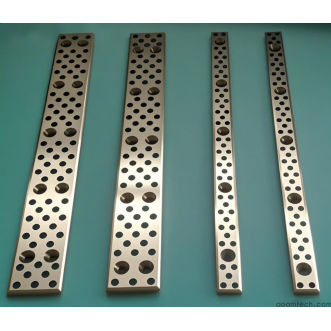

Batchbewerking verwijst naar de productie van identieke aluminiumcomponenten in vooraf bepaalde hoeveelheden met behulp van CNC - technologie. Bij AOOM gebruiken we geavanceerde 3/4/5 - as CNC - machines die aluminiumlegeringen van 100 tot 700 series kunnen verwerken, waardoor de maatnauwkeurigheid binnen ± 0,01 mm wordt gegarandeerd.

Belangrijkste processtappen

1. Materiaalvoorbereiding: Selectie van het juiste aluminiumtype op basis van mechanische eisen

2. Vaste montageontwerp: Aangepaste werkvaststellingsoplossingen voor batch - consistentie

3. Gereedschapspadoptimalisatie: CAM - programmering voor maximale materiaalverwijderingssnelheden

4. Kwaliteitscontrole: In - proces inspectie met CMM en oppervlakrugdetesters

Voordelen van onze batchbewerkingsservice

• Kosteneffectieve productie voor hoeveelheden van 50 - 10.000 + eenheden

• 15 - 30% snellere cycletijden door geoptimaliseerde gereedschapsstrategieën

• Toegewezen productiecellen voor aluminium - specifieke bewerking

• ISO 9001 - gecertificeerd kwaliteitsbeheersysteem

Industrie Toepassingen

Onze batchbewerkingsmogelijkheden dienen:

- Lucht - en ruimtevaart: Structurele componenten en behuizingen

- Automobiel: Motoronderdelen en transmissieelementen

- Elektronica: Koelvlakken en behuizingen

- Medisch: Instrumentatiecomponenten

Met meer dan 12 jaar ervaring in het bewerken van aluminium levert AOOM Technologies betrouwbare CNC - batchbewerkingsoplossingen die precisie, snelheid en kostenefficiëntie balanceren. Neem vandaag contact met ons technisch team op om uw specifieke projectvereisten te bespreken.

Vijf kerntechnologieën voor CNC-bewerking Precisiecontrole v

Vijf kerntechnologieën voor CNC-bewerking Precisiecontrole v

5 Key Control-technieken om vervorming op te lossen bij CNC-

5 Key Control-technieken om vervorming op te lossen bij CNC-

CNC-bewerking van drijfstangen: hoe te zorgen voor boorpreci

CNC-bewerking van drijfstangen: hoe te zorgen voor boorpreci

Chrome Alloy CNC-bewerking _ Wat zijn de bewerkingsmoeilijkh

Chrome Alloy CNC-bewerking _ Wat zijn de bewerkingsmoeilijkh