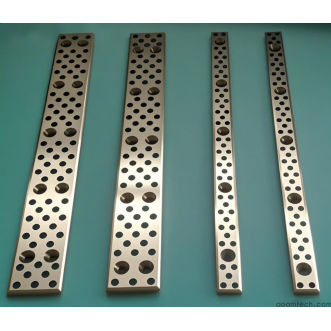

Motoronderdelen CNC bewerkingsproces

Als vakman engine parts CNC - bewerkingsserviceaanbieder specialiseert AOOM Technology zich in het leveren van hoogprecise componenten voor automobiel, lucht - en ruimtevaart en industriële toepassingen. Dit artikel onderzoekt het technische proces, de kwaliteitscontrolemaatregelen en onze concurrentievoordelen op dit gebied.

Waarom kiezen voor CNC - bewerking voor motoronderdelen?

Motoronderdelen vereisen extreme precisie en duurzaamheid. CNC - bewerking biedt micron - niveau nauwkeurigheid (doorgaans ±.005mm) en herhaalbaarheid die cruciaal zijn voor cilinderkoppen, zuigers, koetsiersassen en turbochargerhuizen. Onze 5 - assige CNC - centra kunnen complexe geometrieën in materialen variërend van aluminiumlegeringen tot hoogtemperatuur nikkelsuperlegeringen verwerken.

Onze motoronderdelen productieworkflow

1. Materiaalselectie: We gebruiken gecertificeerde metalen van ruimtevaartkwaliteit (6061 - T6 aluminium, 434 staal, Inconel 718)

2. Precisiebewerking: Multi - assige gelijktijdige bewerking met live tooling

3. Oppervlaktebehandeling: Anodiseren, warmtebehandeling of gespecialiseerde coatings

4. Kwaliteitsinspectie: CMM - meting en druktoetsing

AOOM 's Technische Voordelen

Onze CNC - bewerkingsdiensten voor motorcomponenten kenmerken zich door:

• Meer dan 15 jaar ervaring in de automobielindustrie

• ISO 9001:2015 gecertificeerde productiefaciliteit

• Geavanceerde Zwitserse type draaibanken voor assencomponenten

• 100% materiaaltraceerbaarheidsysteem

Neem voor motoronderdelen die strikte toleranties en betrouwbare prestaties vereisen contact op met AOOM Technology via www.aoomtech.com voor een technische consultatie en offerte.

Vijf kerntechnologieën voor CNC-bewerking Precisiecontrole v

Vijf kerntechnologieën voor CNC-bewerking Precisiecontrole v

5 Key Control-technieken om vervorming op te lossen bij CNC-

5 Key Control-technieken om vervorming op te lossen bij CNC-

CNC-bewerking van drijfstangen: hoe te zorgen voor boorpreci

CNC-bewerking van drijfstangen: hoe te zorgen voor boorpreci

Chrome Alloy CNC-bewerking _ Wat zijn de bewerkingsmoeilijkh

Chrome Alloy CNC-bewerking _ Wat zijn de bewerkingsmoeilijkh