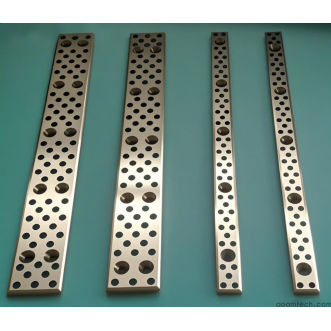

CNC hoge-precisie onderdelen verwerking

In moderne productie is CNC - hoge - precisie onderdelenverwerking een cruciale technologie voor industrieën die nauwe toleranties en uitzonderlijke oppervlakteafwerkingen vereisen. Bij AOOM specialiseren we ons in het leveren van CNC - bewerkingsoplossingen die aan de meest veeleisende specificaties voldoen voor lucht - en ruimtevaart, medische, automobiel en industriële toepassingen.

Wat is CNC hoge - precisie onderdelenverwerking?

CNC hoge - precisie onderdelenverwerking verwijst naar het gebruik van computergestuurde machines om componenten te produceren met een nauwkeurigheid op microniveau. Dit proces omvat geavanceerde CNC - fras -, draai - en meerassige bewerkingsmethoden, waardoor dimensionele consistentie en herhaalbaarheid worden gegarandeerd, zelfs voor complexe geometrieën.

Belangrijkste voordelen van onze CNC High - Precision Machining

1. Tolerantiecontrole: Bereik toleranties zo strak als ± .005mm voor kritieke toepassingen.

2. Materiaal - veelzijdigheid: Verwerk metalen (aluminium, titanium, roestvrij staal), kunststoffen en composieten.

3. Oppervlakteafwerking: Lever Ra .2μm of beter voor functionele en esthetische eisen.

4. Schaalbaarheid: Ondersteun prototypen tot hoge - volume productie met consistente kwaliteit.

Industrieën die wij bedienen

Onze expertise omvat:

Lucht - en ruimtevaart: Motorcomponenten, landing gear - onderdelen.

Medisch: Chirurgische instrumenten, implanteerbare apparaten.

Automobiel: Brandstofinjectiesystemen, transmissieonderdelen.

Elektronica: Koelvlakken, behuizingen met EMI - afscherming.

Waarom kiezen voor AOOM voor CNC High - Precision onderdelen?

1. State - of - the - Art Materiaal: 5 - assige CNC - machines en CMM - inspectiesystemen.

2. ISO 9001 - gecertificeerd: Strenge kwaliteitsbeheer op elke fase.

3. Technische ondersteuning: DFM - feedback om ontwerpen te optimaliseren voor maakbaarheid.

4. Snelle doorlooptijd: Versnelde diensten zonder de precisie te sacrifiëren.

Voor CNC - hoge - precisie onderdelenverwerking die nauwkeurigheid, betrouwbaarheid en kosteneffectiviteit combineert, contacteer AOOM om vandaag uw projectvereisten te bespreken.

Vijf kerntechnologieën voor CNC-bewerking Precisiecontrole v

Vijf kerntechnologieën voor CNC-bewerking Precisiecontrole v

5 Key Control-technieken om vervorming op te lossen bij CNC-

5 Key Control-technieken om vervorming op te lossen bij CNC-

CNC-bewerking van drijfstangen: hoe te zorgen voor boorpreci

CNC-bewerking van drijfstangen: hoe te zorgen voor boorpreci

Chrome Alloy CNC-bewerking _ Wat zijn de bewerkingsmoeilijkh

Chrome Alloy CNC-bewerking _ Wat zijn de bewerkingsmoeilijkh