Hvordan velge en leverandør for CNC Machining Copper Parts

Det er enkelt å finne et verksted som sier at de kan maskinere kobber. But finding the *right* partner who truly understands the quirks of copper and can deliver consistent, precision results? That's where the real challenge begins. ? If you're a procurement manager or an engineer tired of dealing with surface scratches, poor tolerances, or unreliable delivery on your copper components, you're asking the perfect question. Let's break down this selection process, step by step.

Første ting først: Hvorfor er maskinering av kobber så vanskelig?

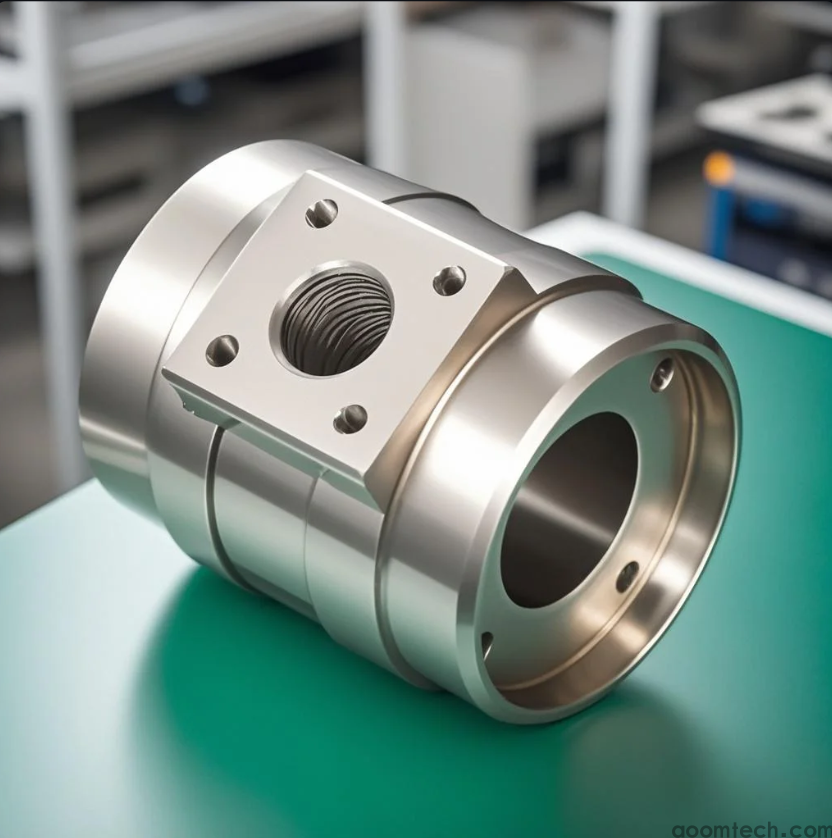

Før vi dykker inn i valg, la oss forstå "hvorfor." Kobber og dets legeringer (som messing og bronse) er fantastiske materialer - stor ledningsevne, korrosjonsmotstand og bearbeidbarhet. However, they can be soft and gummy, which sounds good but can lead to built-up edge on tools, poor surface finish if not handled correctly, and challenges in holding tight tolerances. A supplier who treats copper like steel is a red flag. ?

Trinn 1: Se utover maskinelisten (evaluer ekspertisen deres)

Mange leverandører vil liste opp sine CNC-maskiner. Det er grunnleggende. Du må grave dypere:

• Ask about *specific* experience with copper alloys: "How many projects have you done with C11000 electrolytic copper or C36000 brass?" Real experience matters.

• Inquire about tooling and parameters: Do they use specialized tool geometries or coatings (like diamond-like carbon) for non-ferrous metals? Their answer perhaps hints at their level of sophistication.

• Request case studies or samples: Seeing is believing. A confident supplier can show you finished parts.

Min oppfatning: Jeg ser ofte kjøpere overindeksere på maskinens merkevare. Men en erfaren operatør på en eldre maskin kan overgå en nybegynner på den nyeste modellen når det gjelder fine materialer som kobber.

Trinn 2: Undersøk kvalitetskontrollprosessen

Presisjon er ikke omsettelig. Hvordan garanterer de det?

• First-article inspection (FAI): Do they have a formal process? Will they provide you with inspection reports?

• In-process checks: For longer runs, how do they ensure part 10 is identical to part 1?

• Measurement equipment: Do they have capable tools (like micrometers, CMMs, surface profilometers) to verify the specs *you* care about?

Her er et pro-tips: Spør dem, "What's the most common quality issue you encounter with copper parts, and how do you prevent it?" Their response will tell you volumes about their problem-solving mindset.

Trinn 3: Kommunikasjon og service - Make or Break

Dette kan være det viktigste trinnet. En perfekt del levert sent er ubrukelig. Et lite problem som ikke kan kommuniseres blir tydeligvis et stort problem.

• Responsiveness: Do they answer technical questions clearly and promptly?

• Transparency on challenges: If there's a design for manufacturability (DFM) issue, will they speak up early, or just quote and hope for the best?

• Willingness to collaborate: Are they a true partner for prototyping and refining the design?

Personlig synspunkt: Jeg vil velge en litt dyrere leverandør med feilfri kommunikasjon fremfor en billigere, stille hver dag. De skjulte kostnadene ved feilkommunikasjon er enorme. but speaking of which..., you need to balance cost with all these factors.

Trinn 4: Ikke gjør pris til det første spørsmålet

Vi har alle budsjetter. Men ledende med "hvor mye per stykke?" setter deg i en vare tankegang. Først, fastslå at de er teknisk dyktige og en god passform (trinn 1-3). Then, discuss pricing. A detailed RFQ with clear drawings, material specs, quantities, and tolerance requirements will get you comparable quotes. Be wary of the quote that's drastically lower than others—it often means a compromise somewhere.

Så hva nå? Du har et rammeverk. Det neste trekket er å starte samtaler med potensielle partnere. Når du er klar til å diskutere ditt spesifikke kobberdelprosjekt med en leverandør som får det, er den klareste veien å nå ut direkte. ? Have your drawings ready and start a conversation with our technical team today. We're here to help you navigate from prototype to production, smoothly.

Hvordan velge en pålitelig leverandør av CNC-maskinering for

Hvordan velge en pålitelig leverandør av CNC-maskinering for

Viktige hensyn for presisjon CNC masseproduksjon: En praktis

Viktige hensyn for presisjon CNC masseproduksjon: En praktis

Hvordan forhindre myke materialer fra vridning i CNC-maskine

Hvordan forhindre myke materialer fra vridning i CNC-maskine

Hvordan velge en pålitelig CNC-bearbeidingstjeneste: En prak

Hvordan velge en pålitelig CNC-bearbeidingstjeneste: En prak