Lang aluminiumsplate CNC maskinering prosess

Som en profesjonell leverandør av CNC-bearbeiding spesialiserer AOOM Technology seg på å levere høypresisjons løsninger for CNC-bearbeiding av lange aluminiumsplater for bransjer som spenner fra luftfart til bilindustri. Denne artikkelen utforsker de tekniske aspektene, fordelene og applikasjonene av denne viktige produksjonsprosessen.

Forstå CNC-bearbeiding av lange aluminiumsplater

CNC-bearbeiding av lange aluminiumsplater refererer til den datastyrte subtraktive produksjonsprosessen som brukes på aluminiumsplater med betydelige lengdedimensjoner (vanligvis over 1 meter). Denne spesialiserte prosessen krever avansert utstyr, presise verktøystrategier og ekspertprogrammering for å opprettholde dimensjonsnøyaktighet over hele arbeidsstykket.

Viktige prosesshensyn

1. Materialvalg: Vi jobber med forskjellige aluminiumslegeringer (6061, 7075, 5052) basert på applikasjonskrav

2. Festeinretninger: Tilpassede festeinnretninger og vakuumbord sikrer stabilitet under bearbeiding

3. Optimering av verktøybane: Spesialisert programmering forhindrer vri av verktøyet ved lange skjæringer

4. Varmestyring: Kontrollerte bearbeidings-parameter forhindrer deformasjon på grunn av varme

Hvorfor velge AOOM for ditt prosjekt?

Vårt anlegg for CNC-bearbeiding har:

- Stortformat CNC-fresmaskiner med 5-akseevne

- Høyhastighetsspindler (opp til 24 000 RPM) for overlegne overflatefinish

- Avansert inspeksjonsutstyr inkludert CMM'er

- ISO 9001-sertifisert kvalitetsstyringssystem

Anvendelser over forskjellige bransjer

Denne prosessen er ideell for produksjon av:

- Luftfartsstrukturelle komponenter

- Rammer for halvlederutstyr

- Prototypingdeler for bilindustrien

- Jernbaner for industrielle automasjonssystemer

For ditt neste prosjekt med lange aluminiumsplater, kontakt AOOM Technology på www.aoomtech.com for å diskutere dine spesifikke krav og motta et konkurransedyktig tilbud.

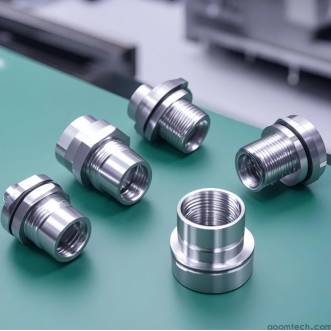

Ikke-standard Precision CNC Machining Produsent Kontaktinfor

Ikke-standard Precision CNC Machining Produsent Kontaktinfor

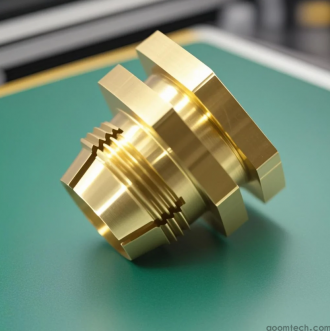

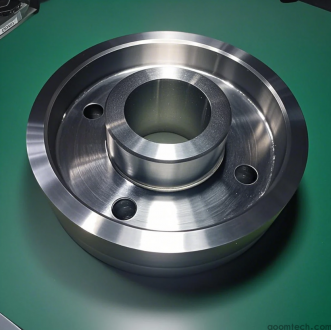

Precision Craft CNC maskinering, Metal Craft CNC maskinering

Precision Craft CNC maskinering, Metal Craft CNC maskinering

Effektiv CNC-bearbeidingsdetaljer, hvordan beregne CNC-bearb

Effektiv CNC-bearbeidingsdetaljer, hvordan beregne CNC-bearb

Varmebehandling og CNC-bearbeidingssekvens, varmebehandling

Varmebehandling og CNC-bearbeidingssekvens, varmebehandling