CNC Machining Tilpasningspris

Når man bestiller tjenester for CNC-bearbeiding, er det avgjørende for innkjøpsansatte og ingeniører å forstå prisen for tilpasninger for å optimalisere budsjetter samtidig som man sikrer presisjonskvalitet. AOOM Technology, som en profesjonell produsent av CNC-bearbeiding, går gjennom de viktigste faktorene som påvirker kostnadene for CNC-bearbeiding for å hjelpe deg med å ta informerte beslutninger.

Nøkkelfaktorer som påvirker priser for CNC-bearbeiding

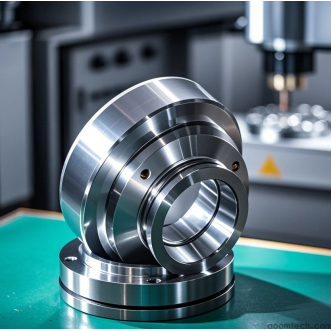

1. Materialvalg: Aluminium, rustfritt stål, titan og tekniske plastmaterialer har varierende råmaterialekostnader og bearbeidings vanskeligheter.

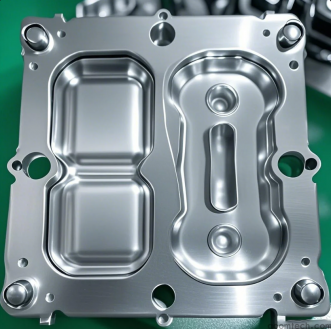

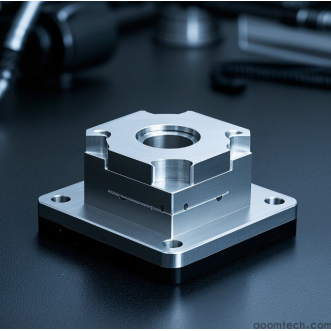

2. Delkompleksitet: Intrikate geometrier som krever fleraksebearbeiding eller strenge toleranser (±.01mm) øker arbeidskraft- og tidskostnadene.

3. Bestillingsvolum: Store bestillinger får vanligvis fordel av økonomier av skala, og reduserer enhetskostnadene.

4. Overflatefinish: Ytterligere prosesser som anodisering eller polering øker den totale prisen.

AOOMs konkurransedyktige prisstrategi

Vårt ISO 9001-sertifiserte anlegg i Kina utnytter:

Avanserte 5-akse CNC-sentre for effektiv produksjon av komplekse deler

Partnerskap med råmaterialleverandører for kostnadsbesparinger

Åpenlyst sitatsystem uten skjulte avgifter

Hvordan få et nøyaktig tilbud?

Send inn CAD-filer (STEP/IGES-format foretrukket) via vår nettside for å motta:

DFM (Design for Manufacturing)-analyse innen 24 timer

Prisoppdeling etter materiale/mengde

Forslag til kostnadsbesparende designoptimaliseringer

Med over 15 års kompetanse innen CNC-bearbeiding gir AOOM Technology en optimal balanse mellom presisjon og overkommelig pris. Kontakt våre ingeniører i dag for å diskutere kravene til ditt prosjekt.

Hvordan finne en pålitelig partner for høypresisjonsblister

Hvordan finne en pålitelig partner for høypresisjonsblister

Din guide til tilpasningstjenester for presisjonsmaskinvare

Din guide til tilpasningstjenester for presisjonsmaskinvare

Hvor mye koster CNC-maskinering med liten batch for tilpasse

Hvor mye koster CNC-maskinering med liten batch for tilpasse

Mastering Composite CNC Machining: Løse vanlige utfordringer

Mastering Composite CNC Machining: Løse vanlige utfordringer