CNC presisjon maskinering tilbud

Når man bestiller tjenester for CNC-presisjonsbearbeiding, er det avgjørende for innkjøpsansatte og ingeniører å forstå faktorene som påvirker sitater for CNC-bearbeiding. AOOM Technology, en pålitelig produsent av CNC-bearbeiding, går gjennom de viktigste elementene som bestemmer prisen og hvordan man kan optimalisere kostnadene uten å kompromitte på kvaliteten.

Faktorer som påvirker CNC-bearbeidingssitater

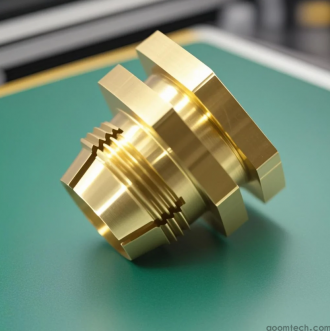

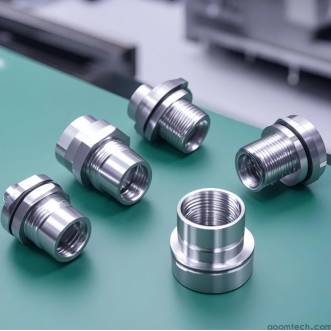

1. Materialkostnader: Typen råmateriale (f.eks. aluminium, rustfritt stål, titan) påvirker prisen betydelig på grunn av varierende markedspriser og bearbeidbarhet.

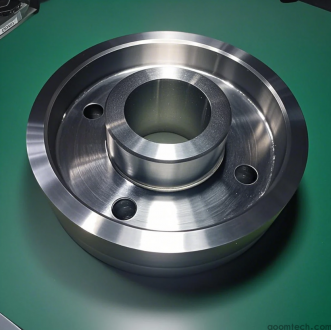

2. Delkompleksitet: Intrikate design med strenge toleranser eller tynne vegger krever avansert verktøy og lengre bearbeidings tid.

3. Produksjonsvolum: Store bestillinger reduserer ofte enhetskostnadene gjennom økonomier av skala.

4. Overflatefinish: Ytterligere prosesser (anodisering, polering) øker det totale sitatet.

5. Leveringstid: Presserende bestillinger kan innebære hastesatser.

Hvordan AOOM optimaliserer dine kostnader for CNC-bearbeiding

AOOM Technology utnytter avanserte 5-akse CNC-maskiner og interne verktøy for å minimere avfall og akselerere produksjonen. Våre ingeniører tilbyr tilbakemeldinger om Design for Manufacturability (DFM) for å forenkle delgeometrien uten å ofre funksjonaliteten, og redusere bearbeidings timer og materialbruk.

Åpenlyst prismodell

Vi tilbyr umiddelbart online tilbud for standardprosjekter via vår plattform (www.aoomtech.com), med detaljerte oppdelinger for tilpassede forespørsler. I motsetning til konkurrentene inkluderer AOOM etterbehandlingskostnader på forhånd for å unngå skjulte avgifter.

For et skreddersydd tilbud for CNC-bearbeiding, last opp dine CAD-filer til AOOM’s sitatssystem eller kontakt vårt ingeniørteam for løsninger for prototyping med høy variasjon og lav volum.

Ikke-standard Precision CNC Machining Produsent Kontaktinfor

Ikke-standard Precision CNC Machining Produsent Kontaktinfor

Precision Craft CNC maskinering, Metal Craft CNC maskinering

Precision Craft CNC maskinering, Metal Craft CNC maskinering

Effektiv CNC-bearbeidingsdetaljer, hvordan beregne CNC-bearb

Effektiv CNC-bearbeidingsdetaljer, hvordan beregne CNC-bearb

Varmebehandling og CNC-bearbeidingssekvens, varmebehandling

Varmebehandling og CNC-bearbeidingssekvens, varmebehandling