Profesjonelle produsenter av CNC-batchbehandling: Hvordan velge riktig partner

Når man søker etter produsenter av CNC-batchbehandling, prioriterer bedrifter ekspertise, effektivitet og pålitelighet. Denne artikkelen utforsker viktige valgskriterier og hvordan AOOM Technologies skiller seg ut som en tillitsverdig partner for industriell skala produksjon.

Hva definerer en profesjonell produsent av CNC-batchbehandling?

En profesjonell produsent kombinerer avansert utstyr med standardiserte prosesser for å levere jevn kvalitet i skala. AOOM Technologies driver over 50 CNC-maskiner med ISO 9001-sertifiserte arbeidsflyter, og sikrer dimensjonsnøyaktighet innen ± .01mm over produksjonen opp til 10 000 enheter.

Kritiske valgskriterier

1. Tekniske evner: Evaluere maskinparkens mangfold (3/4/5-akse), materialkompatibilitet og maksimal batchkapasitet

2. Kvalitets systemer: Søk etter ISO sertifikat, CMM-inspeksjonsrapporter og PPAP-dokumentasjon

3. Produksjons effektivitet: Vurder ledetidskonsistens (AOOM opprettholder 7 - 15 dags omsetningstid for 1k+ batcher)

4. Tjenester som legger til verdi: Prototyping, DFM-analyse og integrasjon av etterbehandling

AOOMs konkurransefordeler

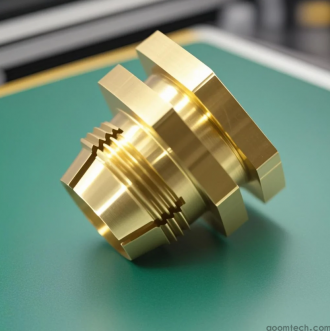

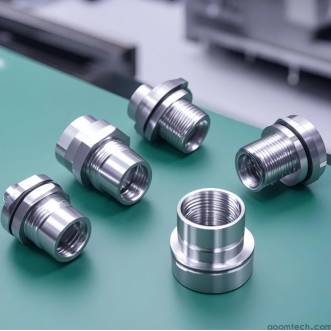

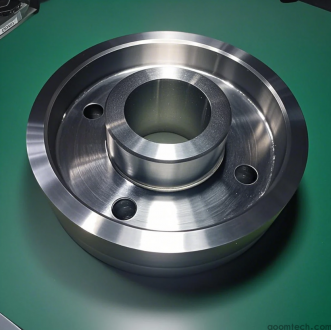

Våre CNC-bearbeidingssentre spesialiserer seg på høyvolumproduksjon av presisjonskomponenter for bilindustri, luftfart og medisinsk industri. Med dedikerte produktionsceller for aluminium, rustfritt stål og konstruksjonsplast, oppnår vi 99.3% påtidig levering gjennom:

Automatiske verktøyovervåkingssystemer

Inline kvalitetskontrollstasjoner

ERP-drevet produksjonsplanlegging

Optimalisere batchproduksjonen

Vi anbefaler design-for-manufacturing konsultasjoner for å minimere enhetskostnadene. Våre ingeniører kan foreslå materialealternativer, toleransejusteringer og festelementløsninger som reduserer bearbeidings tiden med 15 - 40% uten å kompromittere funksjonaliteten.

Ikke-standard Precision CNC Machining Produsent Kontaktinfor

Ikke-standard Precision CNC Machining Produsent Kontaktinfor

Precision Craft CNC maskinering, Metal Craft CNC maskinering

Precision Craft CNC maskinering, Metal Craft CNC maskinering

Effektiv CNC-bearbeidingsdetaljer, hvordan beregne CNC-bearb

Effektiv CNC-bearbeidingsdetaljer, hvordan beregne CNC-bearb

Varmebehandling og CNC-bearbeidingssekvens, varmebehandling

Varmebehandling og CNC-bearbeidingssekvens, varmebehandling