Hvilken presisjon kan CNC 3-akse maskinering oppnå?

Som en profesjonell leverandør av CNC-bearbeidings tjenester forstår AOOM Technology at presisjon er kjernepinnen i utmerkelse i produksjon. Når kunder spør om evnene til CNC 3-aksebearbeiding, søker de vanligvis klarhet om de toleranser og overflatefinish som kan oppnås for deres prosjekter.

Forstå presisjonen til CNC 3-aksebearbeiding

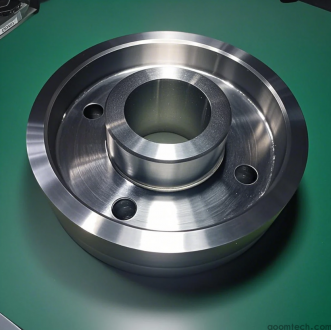

Standard 3-akse CNC-maskiner kan vanligvis opprettholde toleranser på ±.005" (±.127mm) for de fleste materialer, og noen høykvalitetsmaskiner oppnår ±.001" (±.025mm) under optimale forhold. Den faktiske presisjonen avhenger av flere faktorer, inkludert maskinkalibering, verktøyets kvalitet, materialegenskaper og operatørens ekspertise.

Nøkkelfaktorer som påvirker maskinnøyaktigheten

1. Maskinstivhet: Vårt tyske og japanske CNC-utstyr opprettholder en eksepsjonell stabilitet

2. Verktøyseleksjon: Vi bruker premium karbid endemills fra ledende merker

3. Temperaturkontroll: Klimakontrollert verksted forhindrer termisk ekspansjon

4. Målesystemer: Mitutoyo CMM-maskiner verifiserer delens dimensjoner

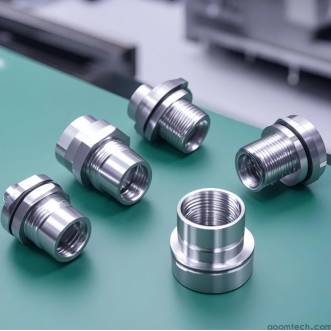

AOOMs presisjons egenskaper

Gjennom våre ISO 9001-sertifiserte prosesser leverer vi konsekvent:

- Standardtoleranse: ±.005" (±.127mm)

- Høypresisjonstoleranse: ±.001" (±.025mm)

- Overflatefinish ned til Ra .8μm (32μin)

Vårt ingeniørteam kan anbefale optimale bearbeidingsstrategier for å balansere presisjonskravene med kostnadseffektivitet.

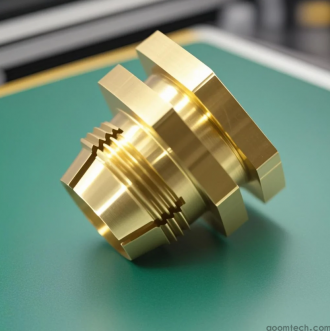

Anvendelser av presisjons 3-aksebearbeiding

Denne teknologien tjener bransjer som krever strenge toleranser:

• Luftfartskomponenter

• Medisinsk utstyrsprototyper

• Bildelkomponenter

• Industrielle automasjonsystemer

Hos AOOM Technology kombinerer vi avansert utstyr med flere tiår med bearbeidingskompetanse for å levere presisjonskomponenter som oppfyller dine nøyaktige spesifikasjoner. Kontakt vårt ingeniørteam for å diskutere prosjektets spesifikke krav.

Ikke-standard Precision CNC Machining Produsent Kontaktinfor

Ikke-standard Precision CNC Machining Produsent Kontaktinfor

Precision Craft CNC maskinering, Metal Craft CNC maskinering

Precision Craft CNC maskinering, Metal Craft CNC maskinering

Effektiv CNC-bearbeidingsdetaljer, hvordan beregne CNC-bearb

Effektiv CNC-bearbeidingsdetaljer, hvordan beregne CNC-bearb

Varmebehandling og CNC-bearbeidingssekvens, varmebehandling

Varmebehandling og CNC-bearbeidingssekvens, varmebehandling