Din guide til tilpassede CNC-maskineringstjenester: Fra prototype til produksjon

Hei der, er du en prosjektleder eller ingeniør som stirrer på en designfil og lurer på, "Can this specific part even be made?" Or maybe you're an entrepreneur with a brilliant product idea, but the thought of manufacturing it feels like a mountain to climb. You keep searching for "custom CNC machining" but find mostly generic info. We get it. The gap between a digital design and a physical, precision part is where projects can stall. But what if you had a clear path to turn your ideas into reality? Let's break it down together. ?️

Hva er egentlig Custom CNC Machining, uansett?

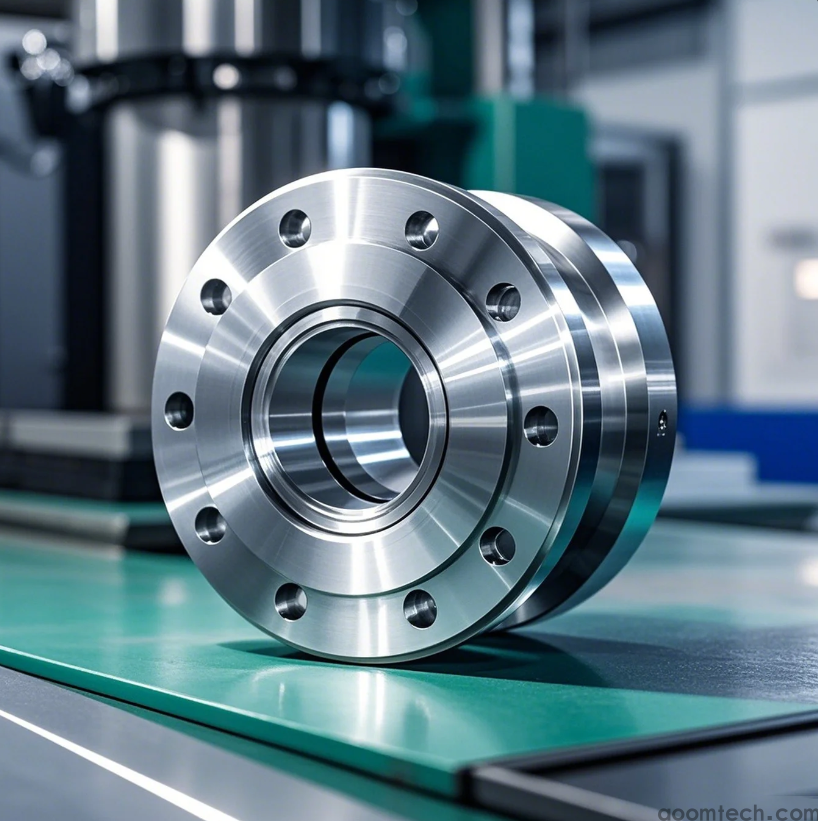

I sitt hjerte er tilpasset CNC-maskinering som en superdrevet, automatisert billedhugger for metall, plast og andre materialer. Du gir en digital tegning (en 3D-modell), og den datastyrte maskinen hugger råmaterialet ditt i en nøyaktig fysisk kopi. Det er metoden når du trenger one-of-a-kind parts or small batches that off-the-shelf components can't satisfy. Think of specialized brackets, unique gears, or prototype housings for a new device you're developing.

Hvorfor ville du velge tilpasset maskinering fremfor standarddeler?

Dette er kjernen i det, ikke sant? Hvorfor gå gjennom trøbbel? Vel, det kommer ofte ned til tre store grunner:

✅ Perfect Fit for Your Design: Your project is unique. Standard parts force you to compromise your design, but custom machining lets you build the part exactly as you envisioned it, with all the specific holes, curves, and threads you need.

✅ Unbeatable Strength and Durability: Parts machined from a solid block of metal are typically stronger than those made by casting or 3D printing with plastic. For parts that undergo stress or need to last, this is a huge win.

✅ Surprising Speed for Prototypes: While setting up takes time, once running, CNC machines can produce functional prototypes incredibly fast. This lets you test and refine your design without waiting for weeks.

Det er imidlertid verdt å nevne at for extremely complex internal geometries, some other technologies might have an edge. The best choice often depends on the specific shape you're trying to create.

Hvordan er den virkelige prosessen? Et trinnvis blikk

La oss avmystifisere reisen fra ideen din til en del i hånden din. Det er ikke så ugjennomsiktig som det virker!

1. You Share Your Vision: It all starts with your 3D CAD file. This is the most important document. The more detailed, the better.

2. A Expert Review (DFM): This is where a good shop shines. They'll look at your design and suggest tweaks—maybe a slightly different corner radius or material—to make it easier, faster, and cheaper to produce without changing its function. It's a collaborative step.

3. The Machine Does Its Magic: The approved design is translated into code, and the CNC machine precisely cuts away material. I always find it mesmerizing to watch ?.

4. The Finishing Touches: The raw machined part might need deburring (smoothing sharp edges), painting, or a special coating to resist corrosion. This step gives it a professional, ready-to-use finish.

Men vent... Hvor mye koster det egentlig?

La oss snakke om det store spørsmålet. Det er ingen enkelt prislapp, men kostnadene henger på noen viktige ting:

• Material Choice: Aerospace aluminum costs more than standard steel. It's that simple.

• Machine Time: Complex parts with lots of fine details take longer to make, and time is money on a machine.

• Setup & Labor: There's initial work to program and set up the machine. This is why per-part cost drops significantly with larger quantities.

Okay, full gjennomsiktighet - den exact pricing algorithms used by different machine shops can be a bit of a black box. The best move is to get a few quotes and ask them to break down the costs for you. This will give you the clearest picture.

Jeg er overbevist! Hvordan får jeg de beste resultatene?

Ønsker du å gjøre ditt første (eller neste) tilpassede maskineringsprosjekt til en jevn suksess? Her er hva jeg har lært:

? Communication is Everything: Don't just email a file and disappear. Talk to your machining partner. Explain the part's function. The more they know, the more they can help.

? Design for Manufacturability (Keep It Simple): The simplest design that does the job is usually the cheapest and fastest to make. Avoid super deep holes or super thin walls if you can.

? Request a Prototype First: For a big order, it's often wise to pay for a single prototype. You can hold it, test it, and make sure it's perfect before committing to the full production run. This saves money and headaches in the long run.

Til syvende og sist er det kanskje det viktigste trinnet å finne en maskineringspartner du stoler på. Det er et forhold. Den rette butikken vil ikke bare være en bestillingstaker; de vil være en konsulent som hjelper deg med å bringe din presise visjon til liv. ?

Hvordan velge en pålitelig leverandør av CNC-maskinering for

Hvordan velge en pålitelig leverandør av CNC-maskinering for

Viktige hensyn for presisjon CNC masseproduksjon: En praktis

Viktige hensyn for presisjon CNC masseproduksjon: En praktis

Hvordan forhindre myke materialer fra vridning i CNC-maskine

Hvordan forhindre myke materialer fra vridning i CNC-maskine

Hvordan velge en pålitelig CNC-bearbeidingstjeneste: En prak

Hvordan velge en pålitelig CNC-bearbeidingstjeneste: En prak